Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

All Categories

Casting

(9)Aircraft parts casting

It is made up of the following components: the head, the head fairing, the oxidizer and fuel (combustion agent) tanks, the instrument compartment, the inter-stage section, the engine thrust structure, the tail compartment, and other components. Separate connection devices are present on the portions that need to be separated.

Casting parts

Premium dimensional accuracy, typically 0.1 mm for the first 2.5 cm (0.004 inch for the first inch) and 0.02 mm for each additional centimeter (dependent on the casting material)

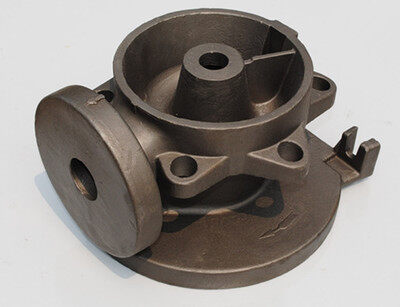

Iron casting

Castings made using the sand casting technique are created in sand molds. Steel, iron, and the majority of non-ferrous alloy castings can be produced using sand casting. Sand casting can be adapted to single-piece manufacturing, batch production, and mass production since the modeling materials used in the process are inexpensive and simple to get, and the molds are simple to build. It has long since evolved into the fundamental step in casting manufacturing.

Lost wax casting

Investment casting, also referred to as lost wax casting, involves procedures like pressing wax, mending wax, putting together trees, dipping slurry, melting wax, and casting molten metal. Making a wax mold of the component to be cast using wax, then covering it with mud to create a mud mold, is known as lost wax casting. Put the dried clay mold in hot water to melt the internal wax mold.

CNC Machining

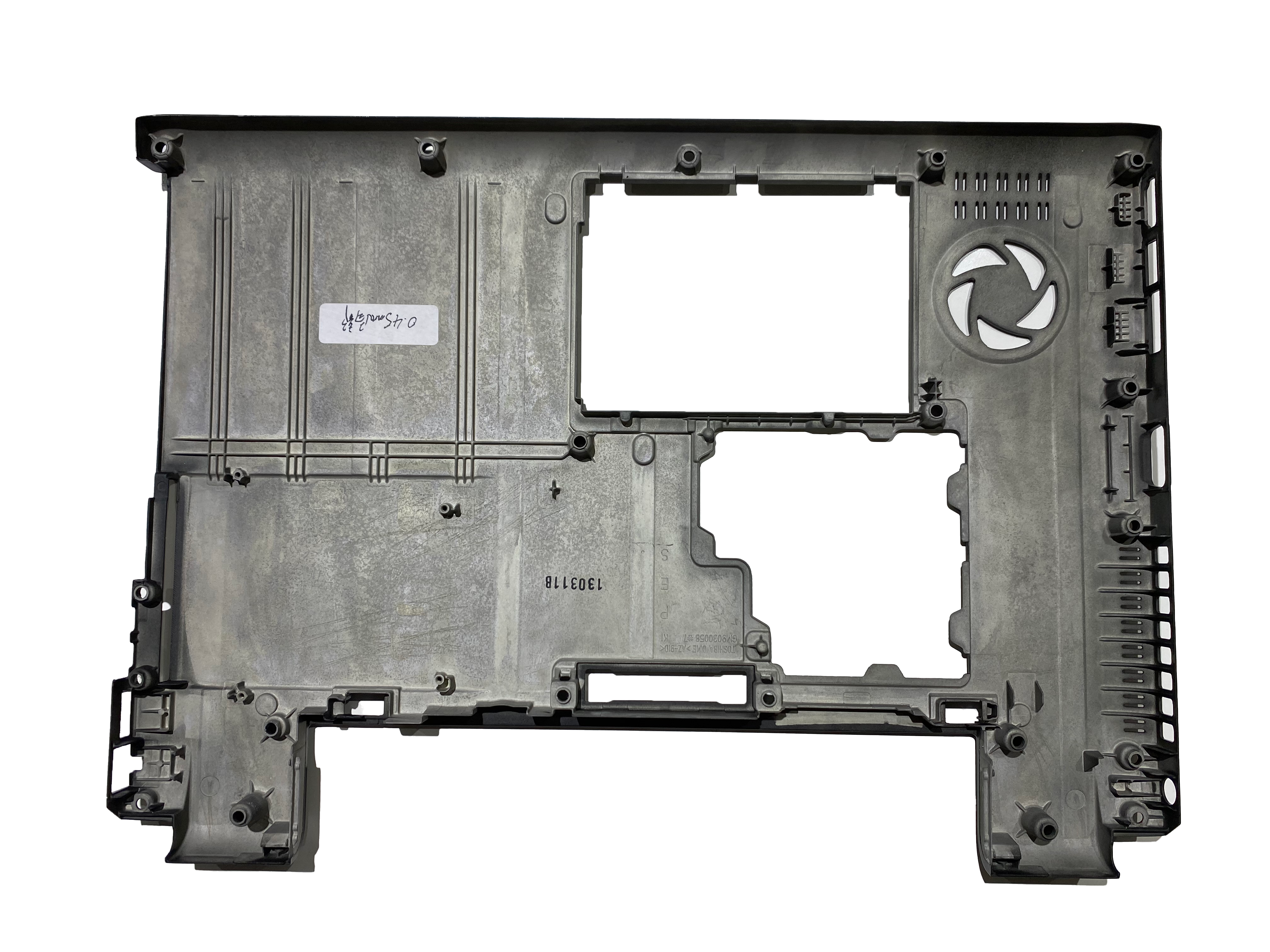

(7)aluminum bracket

CNC machine service is an excellent way to shorten the production cycle and lower the cost of your machinery's component parts. CNC machining services may streamline the manufacturing process, accelerate the mass production of machined parts, and reach a greater level of accuracy by integrating a variety of innovative technology.

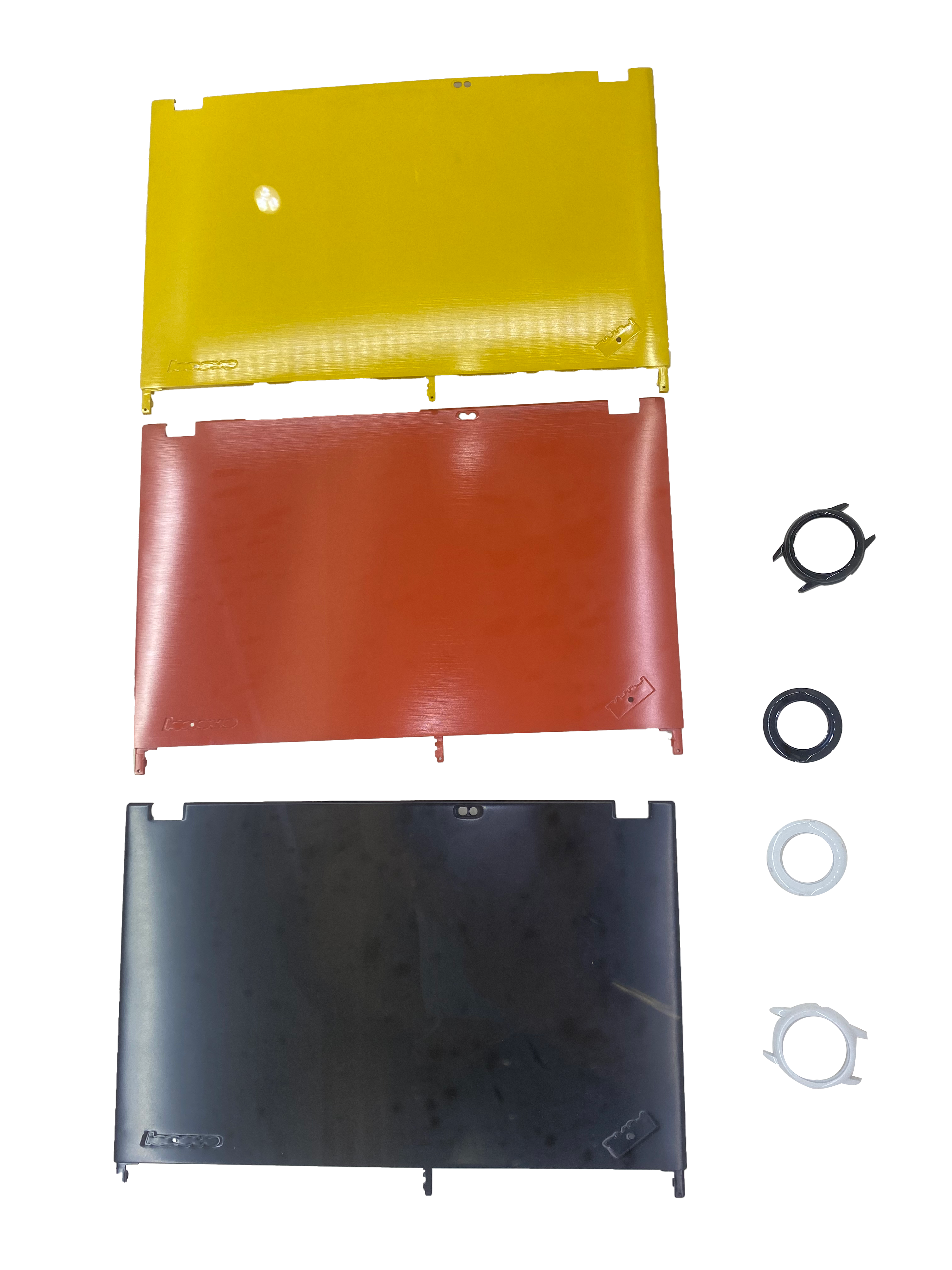

Aluminum panel

Low prices and quality that meets their needs may be the two factors that influence many customers' decisions to use our services. Price is no longer a development factor for determining a qualified supplier, though, as internationalization continues to advance.

CNC Lathe Machining

A number of conventional machining techniques have been replaced by CNC lathe machining, which is a significant one. In the past, parts were produced using human-operated lathe machines. But today, the CNC lathe has gained popularity as a tool for making parts. Even though the method has gained a lot of popularity, not everyone is adept at the fundamentals of CNC lathe machining.

CNC Milling machining

CNC machining is a method that by its very nature offers great levels of accuracy and precision and very little opportunity for error. The reason is that it runs on a computer-driven program and inputs 3D designs created using CAD (Computer-Aided Design). A machine interface is used for every action. For this machine to carry out its instructions, no manual input is required. The highest level of precision is made possible by these automated procedures, ensuring that even the most complicated and finite geometry can be technically handled.

Die casting

(5)Aluminum Die casting

For the automotive, medical, aerospace, electronics, food, construction, security, marine, and other industries, we offer customized die casting services that produce reliable and reasonably priced castings that meet your requirements. Send your inquiry or submit your drawings quickly to receive a free quote as soon as possible.

Precision Die casting parts

Similar to injection molding, aluminum high pressure die casting involves pouring molten cast metal into the mold chamber. Aluminum die casting services can be used to create intricate parts with intricate geometries. Automobile engine blocks, rocker arms, carburetors, water pump housing, gearbox housing, clutch housing, steering housing, and other production parts are among the precision die cast aluminum components.

Die casting

There are numerous process methods used to transform metal materials into the necessary products, including casting, forging, extrusion, rolling, drawing, stamping, cutting, powder metallurgy, and others. The most fundamental, widely utilized, and extensive process method among them is casting. Casting involves pouring molten metal into a hollow mold constructed of materials that can withstand high temperatures, and after condensation, the result is formed with the desired shape.

Die casting service

Drawing Design: Minghe engineers believe that DFM is one of the best techniques for improving the functionality of castings while maintaining their ability to be manufactured. A team of more than ten skilled engineers at Minghe will provide valuable advice on material structure and strike a balance between design, cost, and part property.