Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

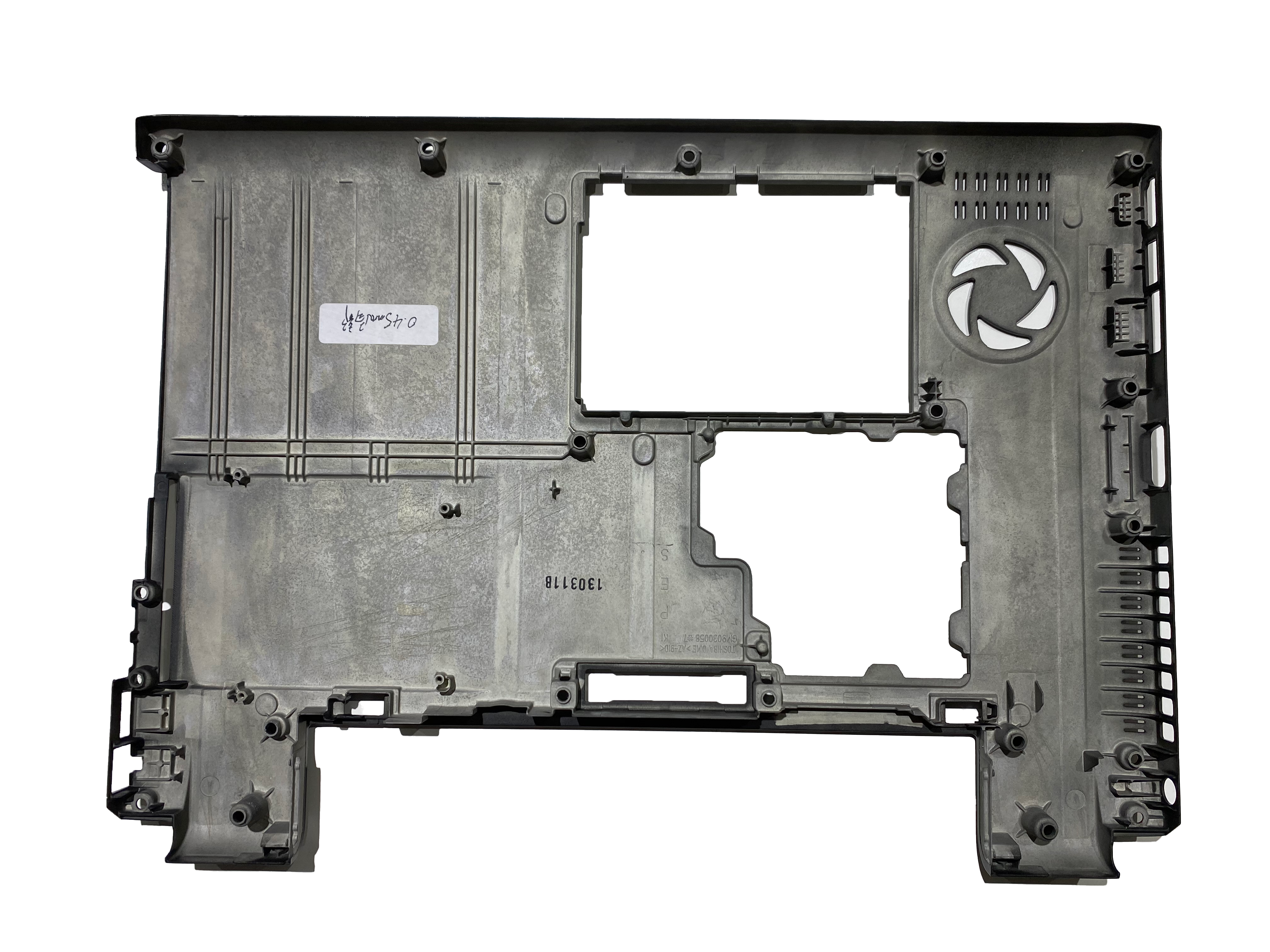

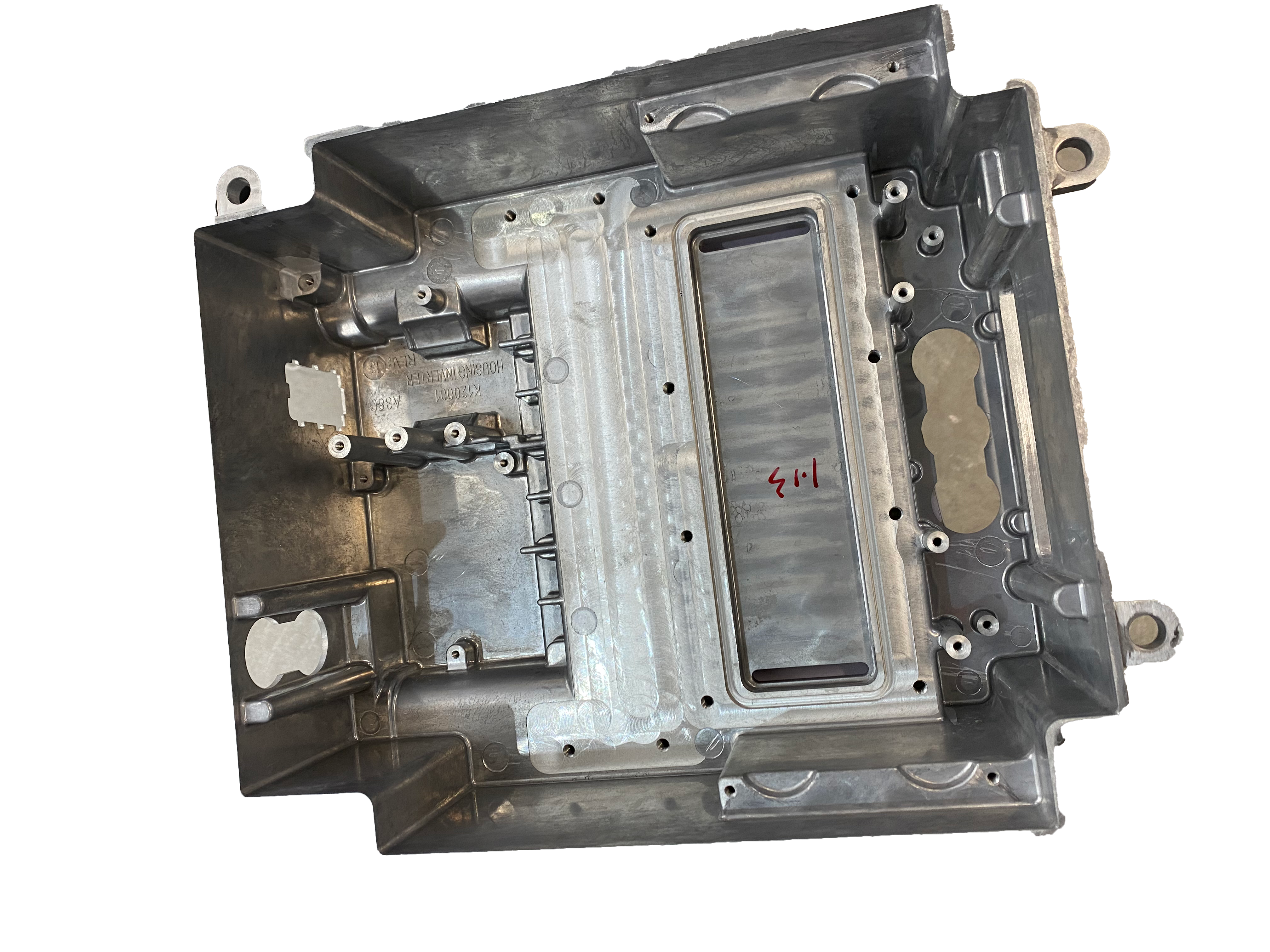

Die casting

Die casting

There are numerous process methods used to transform metal materials into the necessary products, including casting, forging, extrusion, rolling, drawing, stamping, cutting, powder metallurgy, and others. The most fundamental, widely utilized, and extensive process method among them is casting. Casting involves pouring molten metal into a hollow mold constructed of materials that can withstand high temperatures, and after condensation, the result is formed with the desired shape.

Die casting service

Drawing Design: Minghe engineers believe that DFM is one of the best techniques for improving the functionality of castings while maintaining their ability to be manufactured. A team of more than ten skilled engineers at Minghe will provide valuable advice on material structure and strike a balance between design, cost, and part property.

Large Die casting

Whether you only need the product design illustrations or the finished product with exact specifications, Minghe can satisfy your needs with reasonable prices, exceptional efficiency, and top-notch customer service.