Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

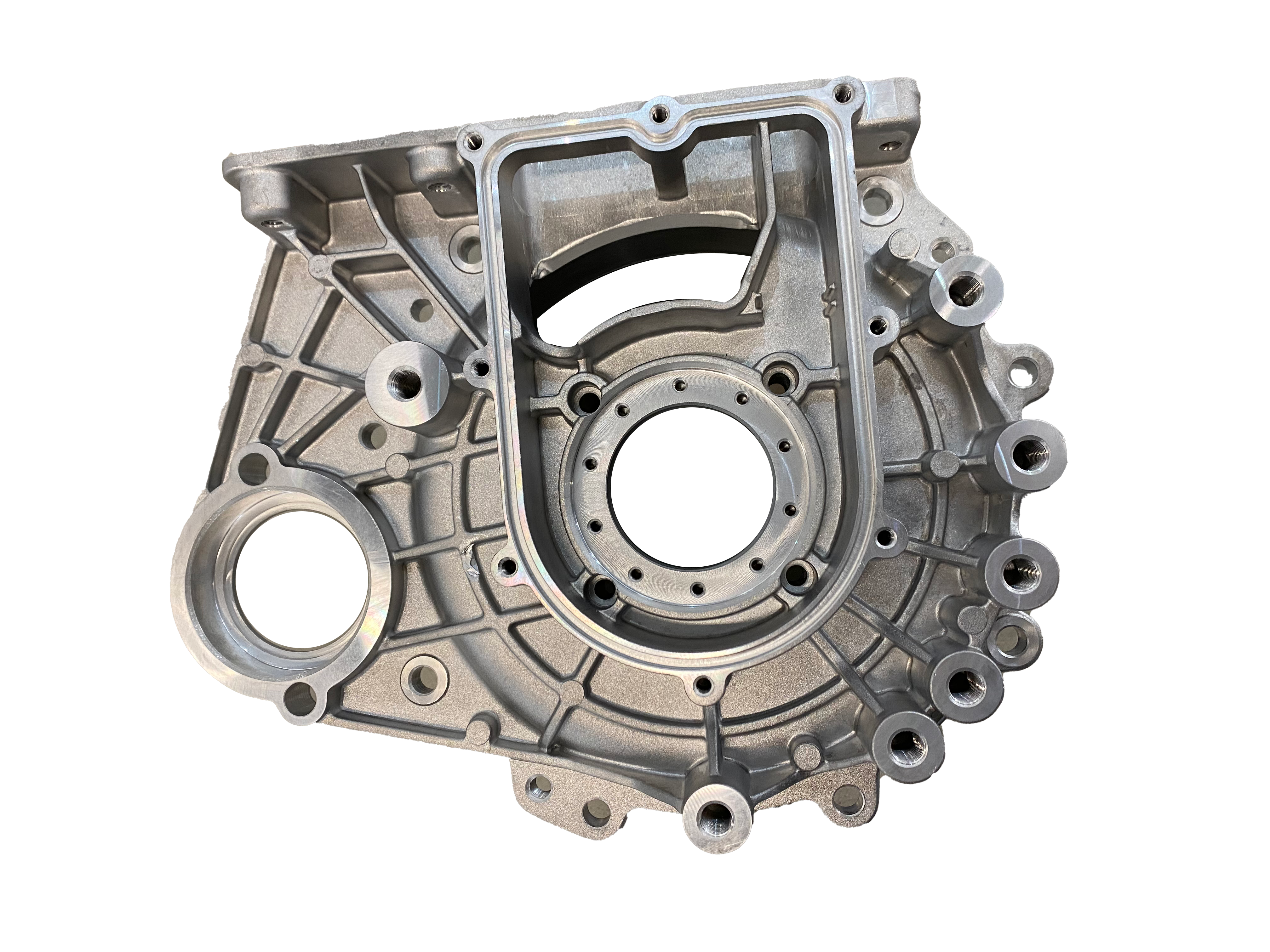

Die casting service

Drawing Design: Minghe engineers believe that DFM is one of the best techniques for improving the functionality of castings while maintaining their ability to be manufactured. A team of more than ten skilled engineers at Minghe will provide valuable advice on material structure and strike a balance between design, cost, and part property.

Company Profile

Minghe is a global, full-service manufacturer of precision die casting products. With more than 35 years' experience in research & development, manufacturing, and precision machining for the aluminum,zinc and magnesium die casting industry, we are proud to work with some of the world's top automotive, engineering, electronics, and telecommunications companies.

We provide experienced engineering, technical management, and quality assurance teams ready to support the most challenging projects. We have assisted clients with precision machined prototypes, die design, extensive product testing, and volume manufacturing.

Minghe Parts Manufacturing Capability

Drawing Design: DFM is one of the best methods followed by Minghe engineers to optimize the manufacturability of castings while retaining functionality. Minghe has a team of more than ten accomplished engineers who will offer helpful suggestions on material structure and find a balance among design, cost and part property.

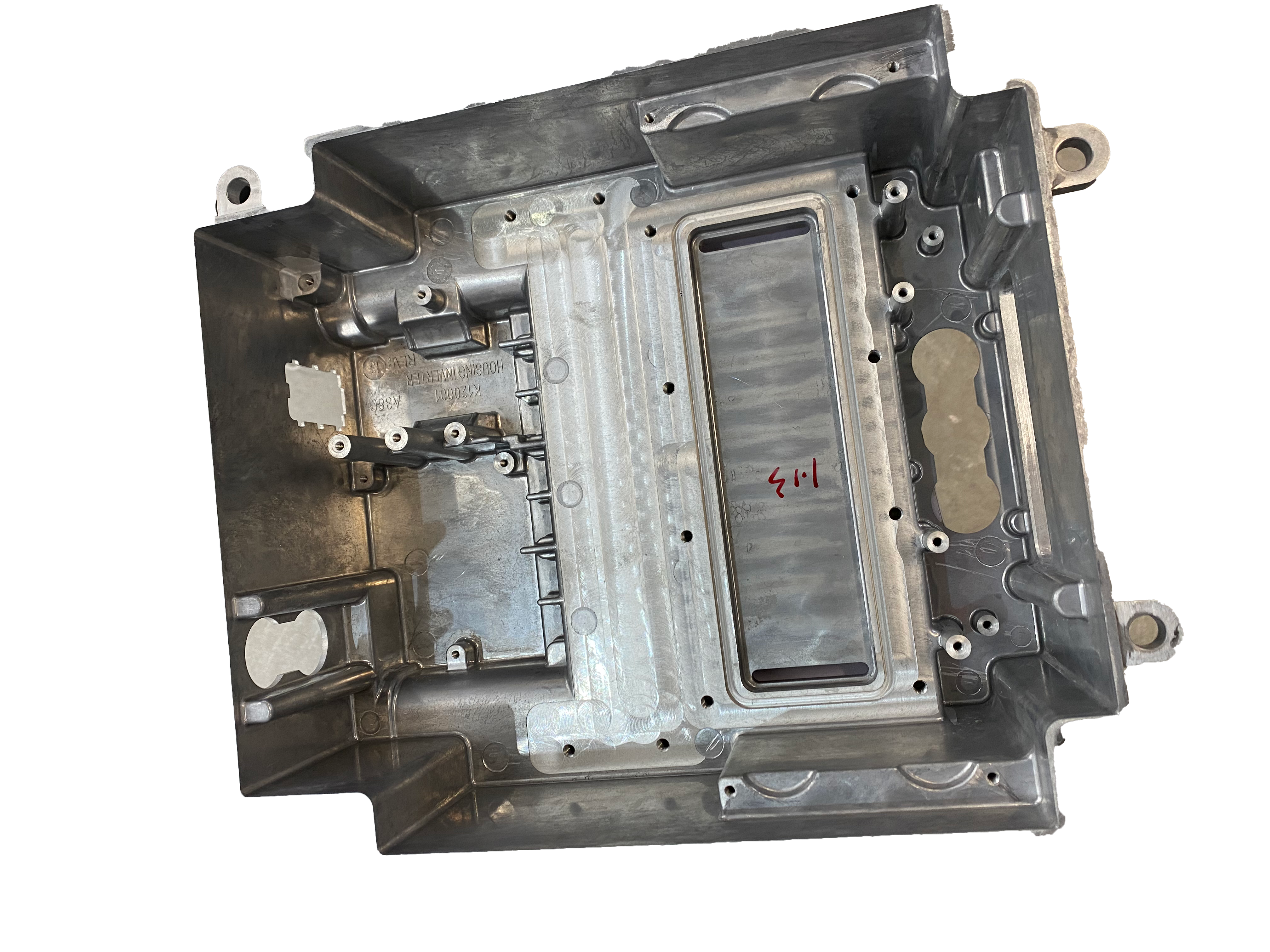

Mold Design: The mold stage simulates the filling flow and solidification process, predicts the defects that will appear in the die casting, and predicts the microscopic metal and mechanical properties, and the strength of the mold ejector pin. Optimize runner and gate design, improve production process parameters, reduce R&D and production costs, and improve casting product quality.

Mold Manufacturing: Minghe's multi-slider mold and mildew manufacturing innovation enables us to put the component structure into the mold and mildew to the greatest extent when making the mold, as well as the parts are developed at one time, minimizing the expense of multi-component production and also assembly and additional handling.

Die Casting Capability: Minghe is among the few companies with the capacity to broaden the casting range, with die spreading devices of 58-3000 tons of different tonnage. It can create components weighing 5g-35kg. The independent furnace of each die casting maker enables us to provide a range of light weight aluminum, zinc, magnesium and their alloys to satisfy the unique requirements of customers.

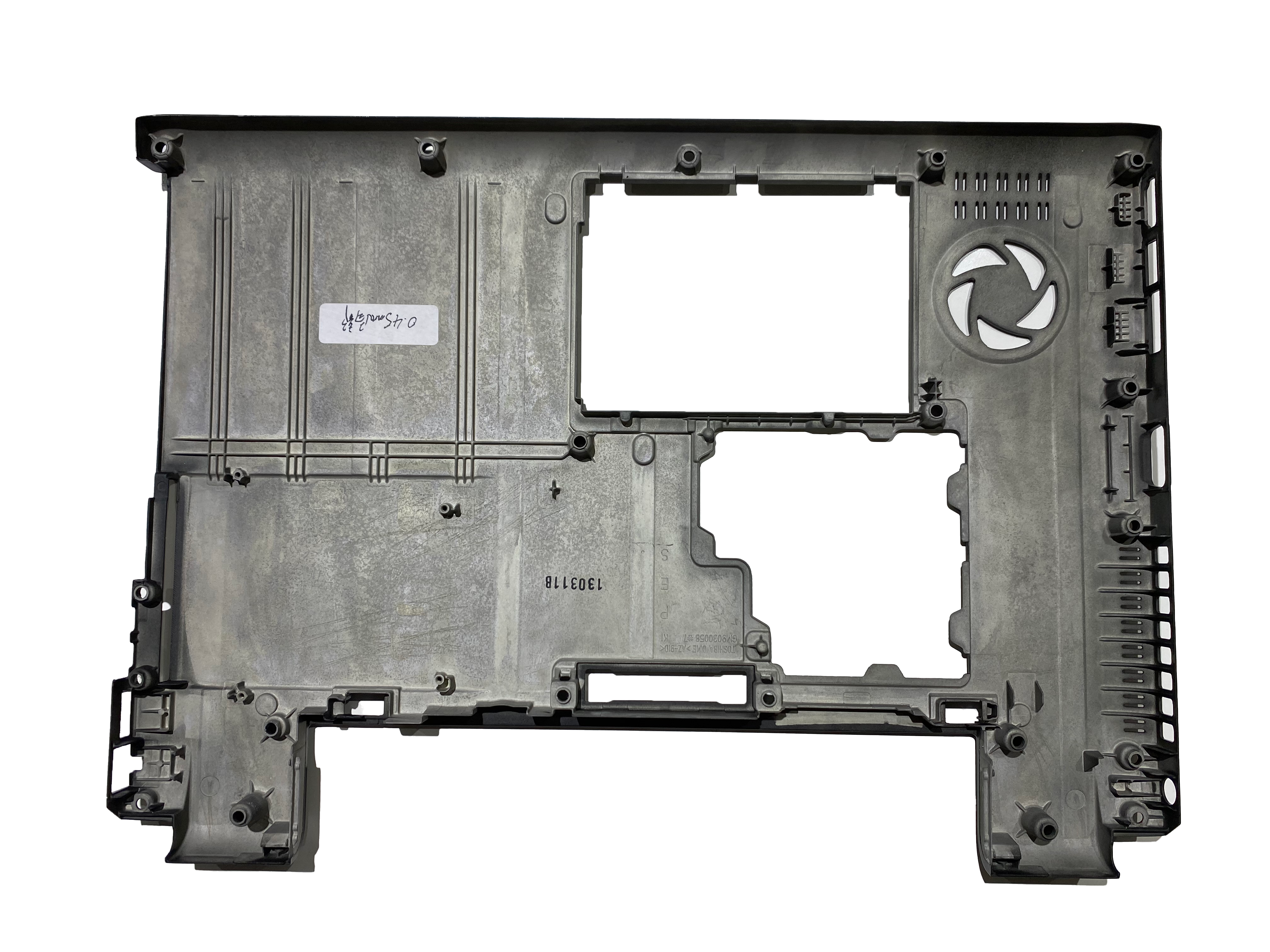

CNC Machining Capability: Minghe has a knowledgeable and also fully grown cnc machining group, more than ten imported handling centers as well as lathes, and also its own handling brand PTJ Shop is one of the top ten small and medium-sized handling makers in China. It offers reliable precision for processing. The minimum resistance is regulated by 0.22 mm to fulfill the requirements of parts. Assembly needs on the customer side.

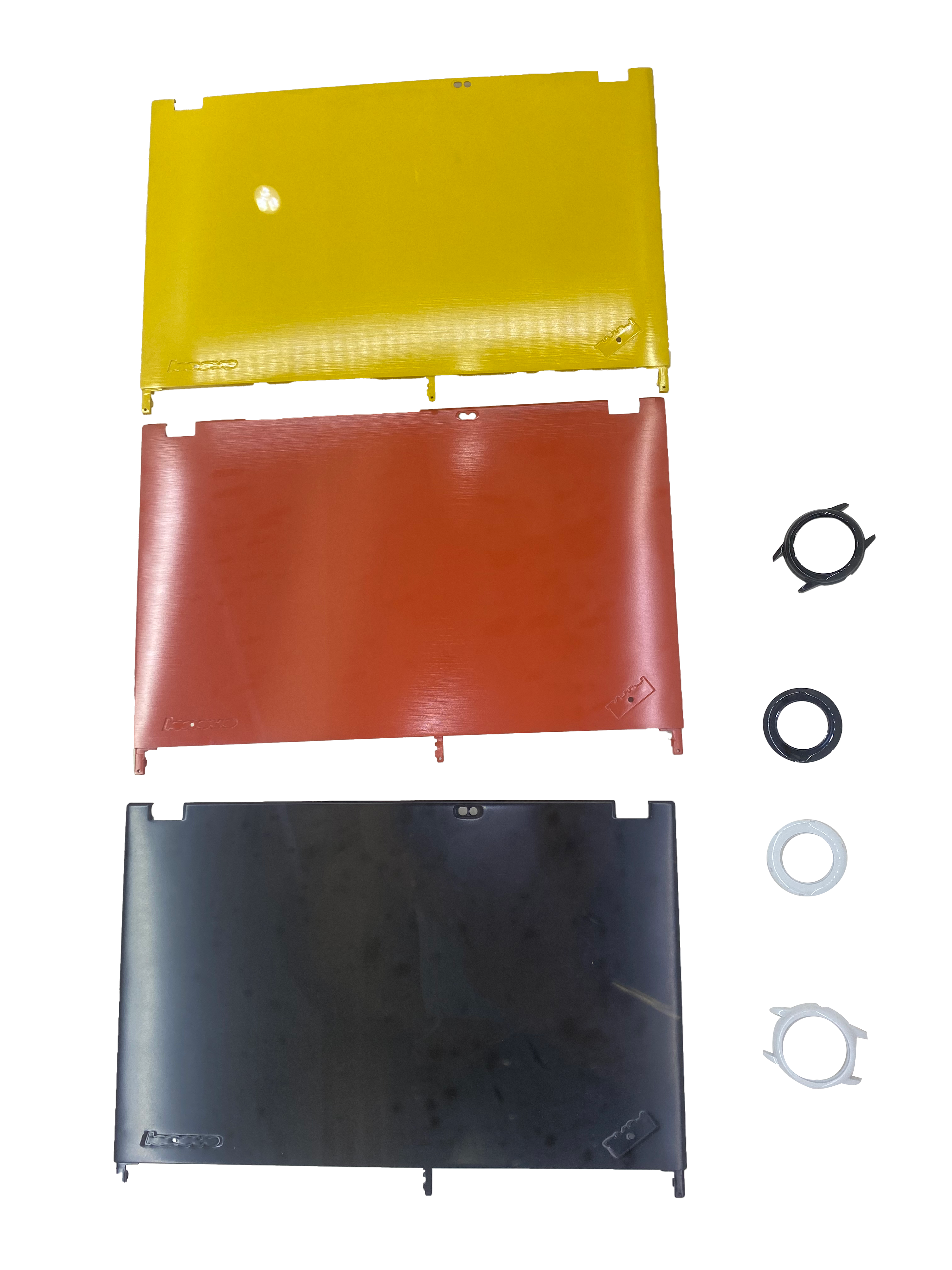

Surface Treatment Capability: Minghe can finish the physical surface therapy as well as powder spraying therapy such as shot blasting, great sand, coarse sand and so on. At the same time, Minghe has been deeply involved in the neighborhood supply chain for greater than thirty years, strategically incorporating loads of chemical surface area treatment suppliers, and also via the administration of intricate supply chains, to offer clients with surface therapy such as plastic splashing, painting, anodizing, electrophoresis, chrome plating, and so on.

Assembly Capability: Minghe offers customers with a selection of mechanical assembly and sub-assembly solutions. We have considerable experience in setting up equipment, including screws, screws, screws, pins, inserts, gaskets as well as O-rings, and stress seal testing to ensure product performance.

Quality Inspection System: Minghe pays unique attention to the quality control of the mass production procedure and also has actually developed a full high quality assessment procedure as well as system. Five tools are commonly made use of: PPAP, APQP, PFMEA, SPC, and also MSA. All items are fully evaluated or created in accordance with the criteria. Testing equipment includes: spectrometer, extending Testing equipment, CMM three-coordinate, pass-stop scale, identical gauge, numerous calipers, etc, to accomplish the control capability of the top quality system.

FAQ

How to order?

First, Customer could send us your sample or drawing, such as 2D and 3D drawing(IGS or STP format). Second, Our engineers will check the drawing carefully and then provide you a better price. Thirdly, If you accept, then order confirmed.

Where is your factory?

Our factory located on Dongguan which is a beautiful city which is very near Guangzhou and Shenzhen. You can fly to Shenzhen Bao'an International Airport (ZGSZ) or Guangzhou Baiyun International Airport (ZGGG), we will pick you up at the airport.

Are you a factory or trade company?

We are a factory. We provide you one-stop service, from mold design to finish part.

How to ship?

The sample of die casting and CNC machining or small order is usually sent by TNT, FEDEX, UPS etc, and the big order is sent by air or sea after confirmation of clients.

What is your terms of payment ?

Die casting mould payments: advanced payment 40% after contract signing;

The 60% balance will be paid after approval of mould by customer.

The payment term of die casting orders: T/T, 30% as deposit be paid before production by T/T, 70% be paid before delivery.