Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

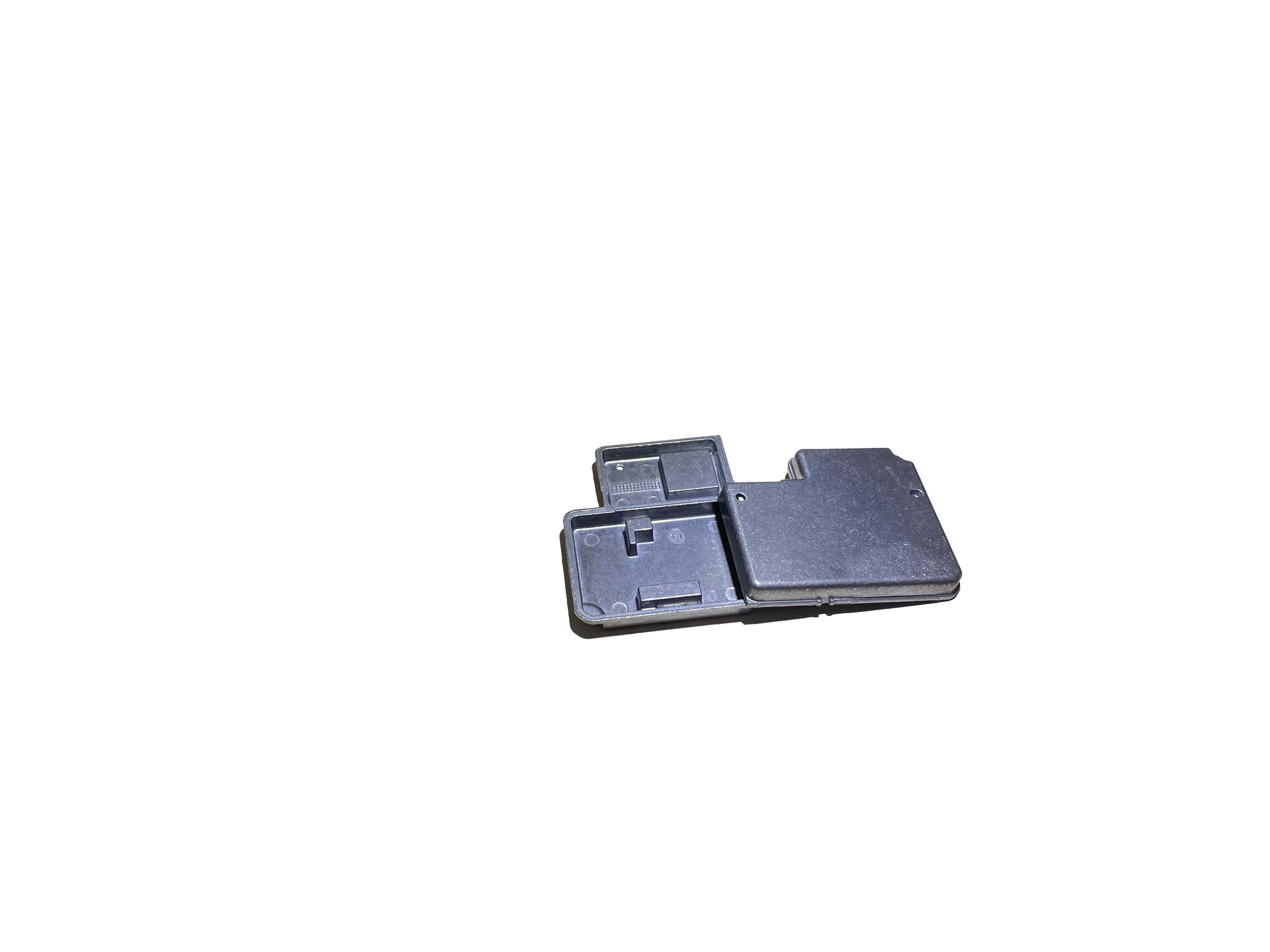

Magnesium alloy casting

Magnesium alloy casting

(5)Magnesium die casting

Magnesium is more expensive than aluminum and zinc. Therefore, it is not the best option for a production solution that is economical. Aluminum is about 35% heavier than magnesium. Therefore, it is primarily employed by automakers to reduce overall vehicle weight.

Magnesium alloy casting

Magnesium is less stable, softer, and more prone to bending than aluminum when put under stress. It is also more expensive than aluminum, making it less desirable. In addition, magnesium has a melting point that is higher than that of zinc, which may increase the cost of casting.

Magnesium casting

Are you trying to find a manufacturer of die cast components with experience and reliability who can machine quality magnesium alloy parts? Your best option is Minghe's bespoke die casting services. We can produce simple and sophisticated magnesium products, including high quality precision magnesium die casting components, investment casting magnesium components, and high pressure die casting magnesium components to fulfill your needs. We have more than ten years of experience in magnesium die casting.

Magnesium alloy parts for automobile

A type of magnesium alloy that is appropriate for casting parts is magnesium alloy die casting, which is based on magnesium and alloying elements. Cast magnesium alloy and wrought magnesium alloy are two different types of magnesium alloy based on the forming technique. They are very dissimilar in terms of composition, microstructure, and characteristics. Cast magnesium alloy is mostly utilized for electrical, mechanical, and vehicle parts. The main uses for wrought magnesium alloy are thin plates, extrusion parts, forgings, etc.

Automotive magnesium alloy

The life of the die can be greatly extended when compared to die casting of aluminum. This is due to the heat transmission properties of magnesium and its decreased affinity for iron, which leads to negligible soldering and less erosion.