Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

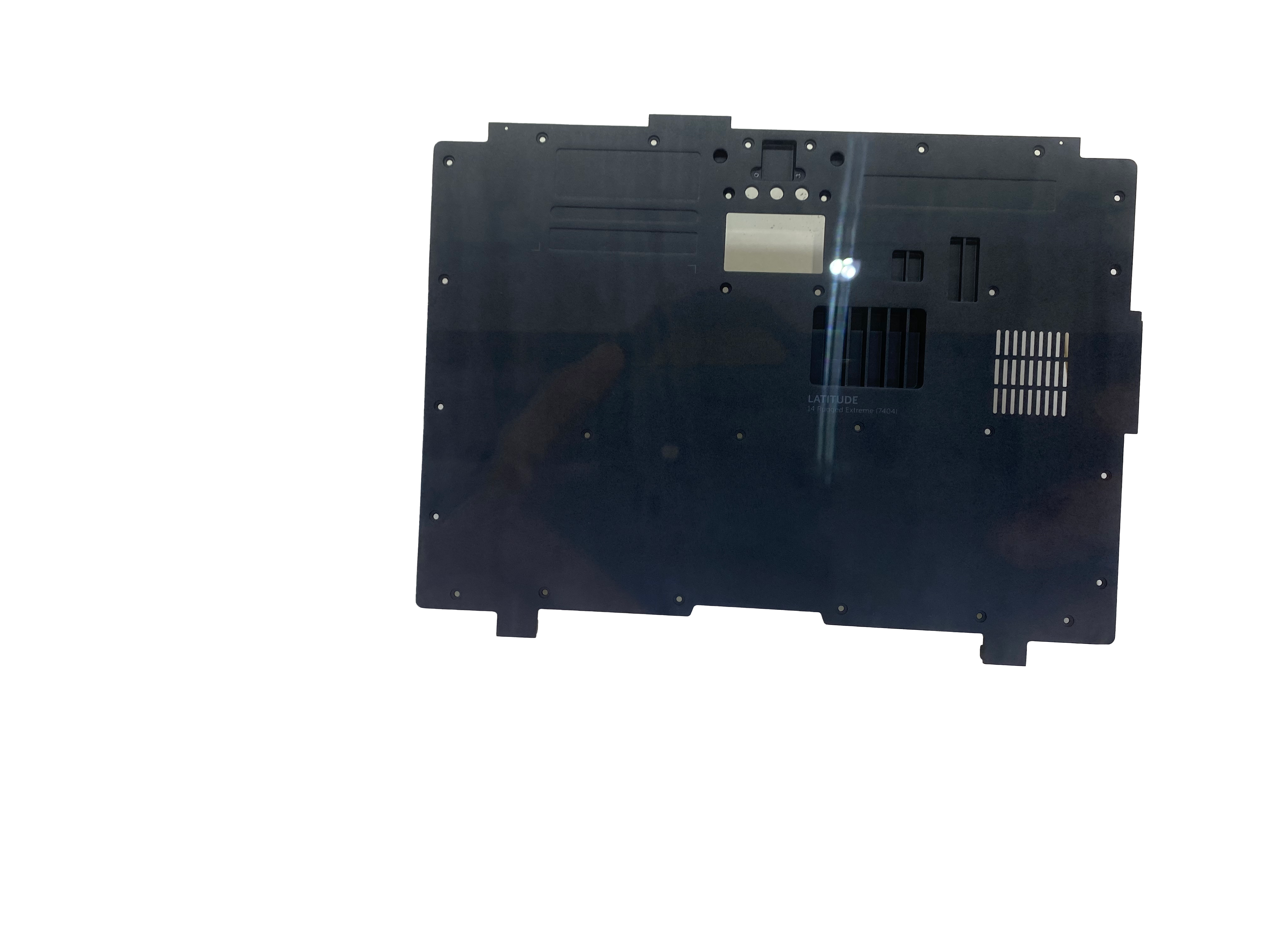

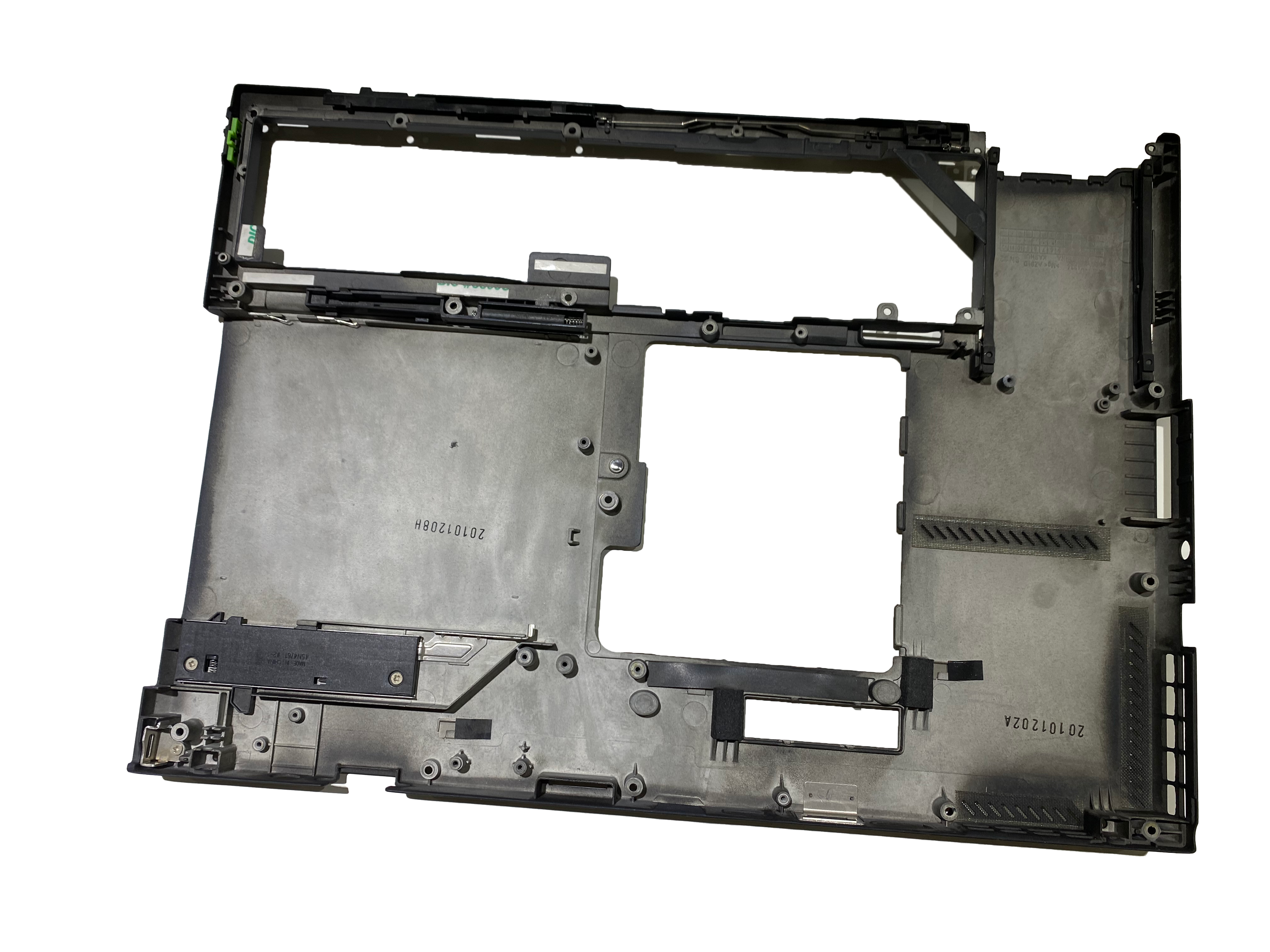

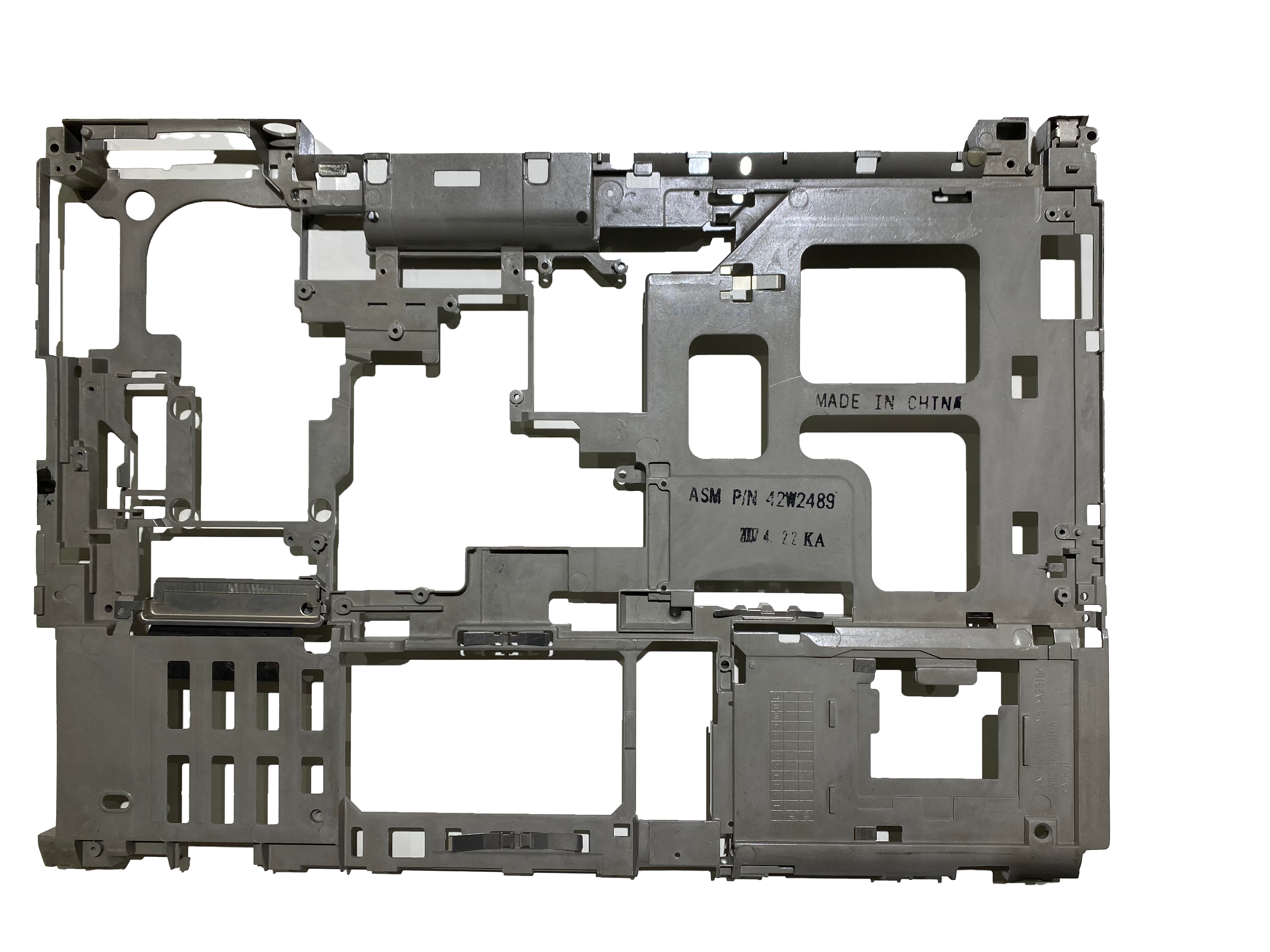

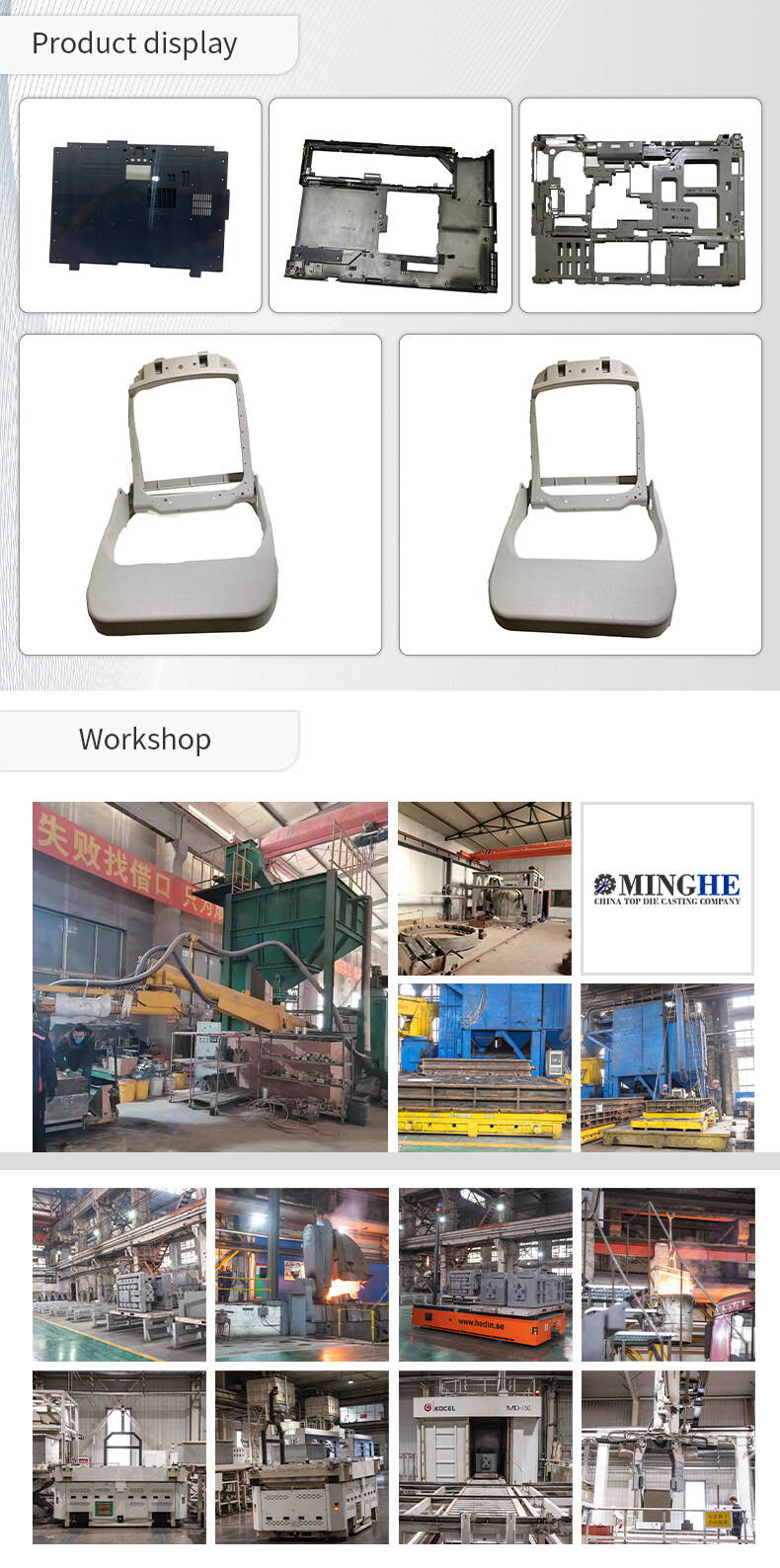

Automotive magnesium alloy

The life of the die can be greatly extended when compared to die casting of aluminum. This is due to the heat transmission properties of magnesium and its decreased affinity for iron, which leads to negligible soldering and less erosion.

Company Profile

Minghe is a global, full-service manufacturer of precision die casting products. With more than 35 years' experience in research & development, manufacturing, and precision machining for the aluminum,zinc and magnesium die casting industry, we are proud to work with some of the world's top automotive, engineering, electronics, and telecommunications companies.

We provide experienced engineering, technical management, and quality assurance teams ready to support the most challenging projects. We have assisted clients with precision machined prototypes, die design, extensive product testing, and volume manufacturing.

Considerations of Magnesium Alloy Die Casting Production

Die Life

Compared to die casting of aluminium, the die life of can be significantly improved. This is because of the heat transfer characteristic and the reduced affinity with iron of magnesium, resulting in negligible soldering and reduced erosion.

Productivity

Because the heat content of magnesium is lower than aluminium, the metal solidifies at a faster rate, generates shorter cycle times, typically by 15-25%. Exceptional dimensional stability of the as-cast product is a particular characteristic of cast magnesium alloys. Frequently, annealing or stress relieving treatments are not required with magnesium, contrary to experiences with some cast aluminium components where some growth continues as natural ageing effects occur over extended times at moderate to elevated temperatures. Machinability is outstanding, exhibiting the best characteristics of all the structural materials viz reduced machining time, lower power requirements, longer tool life, excellent surface finish frequently with a single cut and minimal tool build-up with lower overall machining costs.

Sensitivities

During the die casting cycle each part of the casting will develop a microstructure governed by the local solidification rate and pattern. Correct design of the casting and its feeding system are essential to ensure a uniform and directional solidification pattern. Where this is not achieved, it is to be expected that a certain fraction of microporosity will form due to volume contraction during solidification. This will inhibit the achievement of the excellent properties attainable in die cast magnesium. Ductility is a significant process-sensitive parameter with the control of inhomogeneities, defects and process of paramount importance in realising the potential for structural applications.

FAQ

How to order?

First, Customer could send us your sample or drawing, such as 2D and 3D drawing(IGS or STP format). Second, Our engineers will check the drawing carefully and then provide you a better price. Thirdly, If you accept, then order confirmed.

Where is your factory?

Our factory located on Dongguan which is a beautiful city which is very near Guangzhou and Shenzhen. You can fly to Shenzhen Bao'an International Airport (ZGSZ) or Guangzhou Baiyun International Airport (ZGGG), we will pick you up at the airport.

Are you a factory or trade company?

We are a factory. We provide you one-stop service, from mold design to finish part.

How to ship?

The sample of die casting and CNC machining or small order is usually sent by TNT, FEDEX, UPS etc, and the big order is sent by air or sea after confirmation of clients.

What is your terms of payment ?

Die casting mould payments: advanced payment 40% after contract signing;

The 60% balance will be paid after approval of mould by customer.

The payment term of die casting orders: T/T, 30% as deposit be paid before production by T/T, 70% be paid before delivery.