Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

News

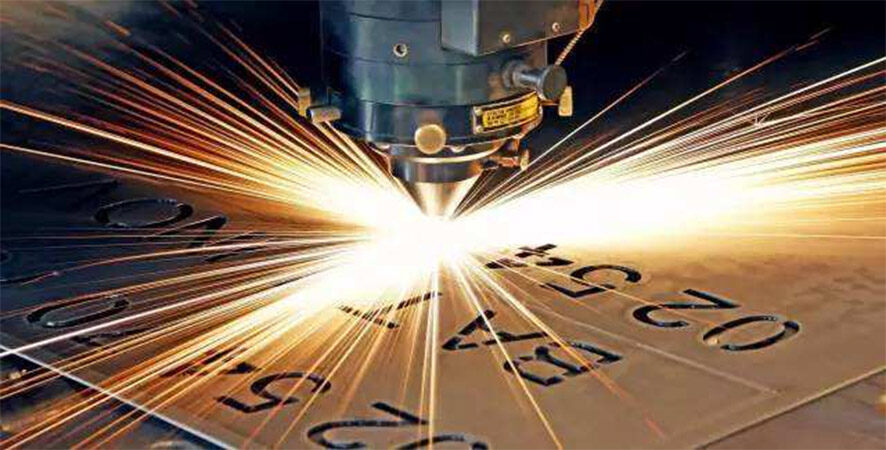

What are the Uniqueness of CNC Laser Cutting Machine?

2022-07-23 10:25:58

The use of numerical control laser cutting machines can bring greater convenience and ensure the accuracy of cutting materials. The prominent feature is that the operation of the cutting machine is more convenient. Because it is a numerical control operation, the cutting process will be more convenient and save the investment of human resources. So, in addition, what are the advantages of a laser cutting machine? Let's have a look.

Advantages of laser cutting machine

- Simple operation: because the equipment has laser transmission characteristics, all numerical control can be realized in the whole cutting process. It can be cut off by changing the NC program during operation. The operation is simple.

- Labor saving: as mentioned above, the operation is convenient, and the numerical control operation can allow one person to operate multiple devices at the same time. Unlike in the past, people also need to carry a large welding gun when cutting manually. The pipe laser cutting machine is fully automated, which can automatically load and unload materials, automatically cut off, and automatically cut off the head and tail of materials, eliminating the step of automatic slag removal and saving a lot of steps. Therefore, the operation process can be fast and simple.

- Efficiency with fewer consumables: for example, the CNC laser cutting machine is ready to cut stainless steel pipes with a diameter of 114mm and a thickness of 1mm. The cut-off time only takes a few seconds. Laser cutting is not in direct contact with the pipe. No tool wear. The tail of the cutting material is less than 40mm. Therefore, the loss of cutting products is relatively small.

- High cutting quality: pay attention not only to the speed of cutting but also to the quality of cutting when cutting metal pipes. When laser cutting is used, the surface of metal pipes becomes clean, and the cutting dimensional accuracy reaches 0.1mm, without secondary processing. In addition, after the laser cutting of the pipe, the width of the heat-affected part is small, and the performance of the material near the slit is hardly affected. The cutting quality will be guaranteed.

There are five main techniques for NC laser cutting:

- Bifocal laser cutting head is a vulnerable part of numerical control laser cutting. Long-term use will damage the laser cutting head.

- Check the straightness of the CNC laser cutting track and the verticality of the machine every six months. If any abnormality is found, it will be maintained and debugged in time.

- Use the vacuum cleaner to remove the dust and dirt on the machine once a week. All electrical cabinets need to be closed to avoid dust.

- Frequently check the steel strip cut by a CNC laser to ensure its compactness. Otherwise, if there are any problems in the operation, serious ones may cause personal injury or even death. The steel belt looks like a small thing, but the problem is still a little serious.

- The guide rail of the CNC laser cutting machine should be cleaned frequently to remove dust and other debris. To ensure the normal operation of the equipment, the screen should be cleaned frequently and filled with grease to ensure that there is no debris in the lubrication. The guide rail needs regular cleaning and lubrication, and the motor also needs regular cleaning and lubrication. The machine moves better, cutting more accurately, and the quality of cutting products will be improved.

For more information about acp sheet cnc cutting, gippsland cnc cutting, mdf sheet cnc cutting, plz feel free to contact us.

Contact us