Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

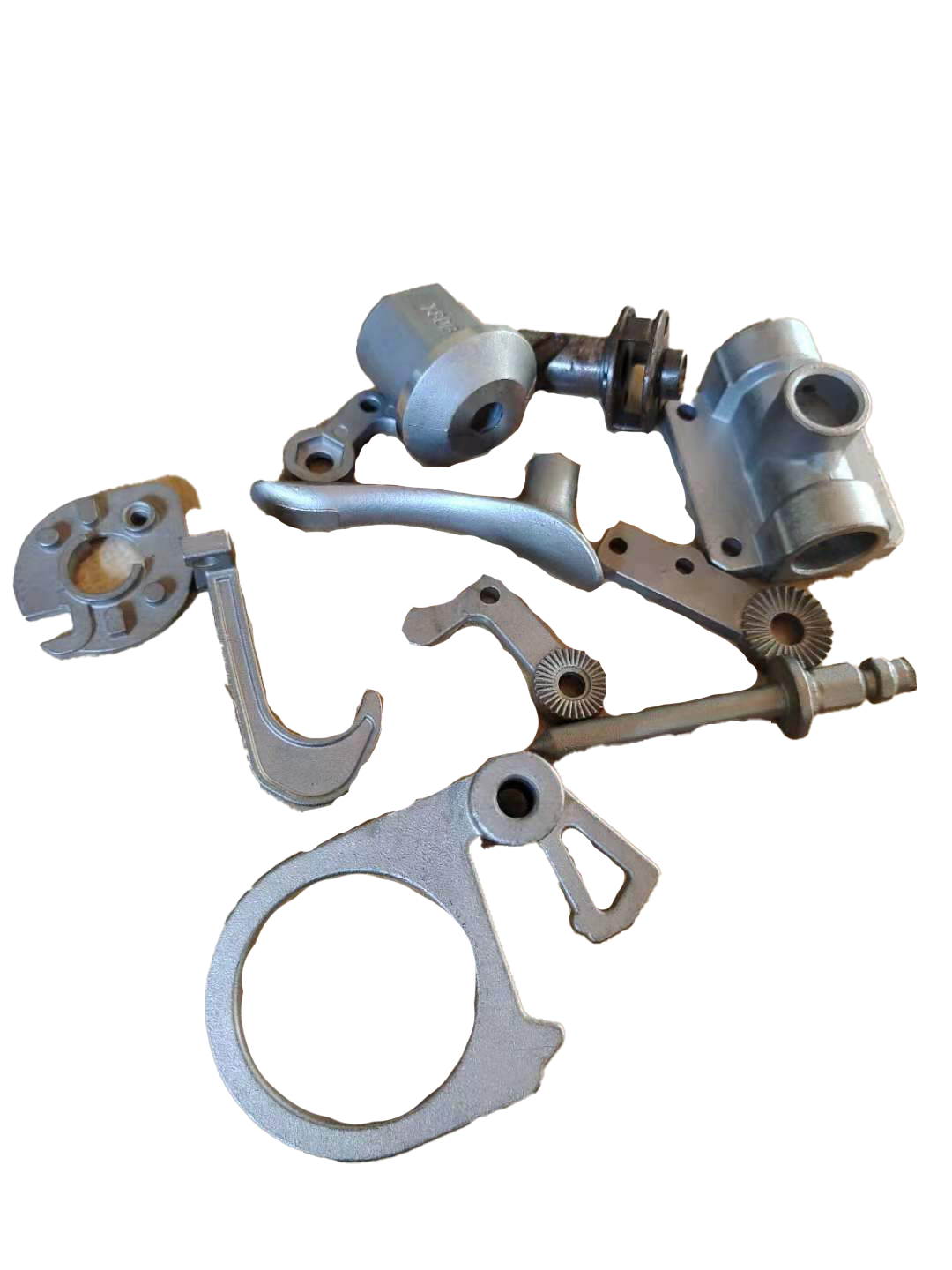

The Difference Between Resin Sand Casting and Precision Casting

Resin sand casting model is a foundation for resin sand casting manufacturers to obtain castings, and it is also a very critical step. The draft angle of the pattern is generally 1:30, and the roughness of the surface of the model is recommended to be based on a level higher than the smoothness and roughness of the casting, so that the drawing process can be satisfied with the casting surface. quality requirements.

The difference between resin sand casting and precision casting

Generally, the precision should be between Ra125-Ra25, and the model should be treated with putty and gauze about 2-3 times, so as to meet the technical requirements. The model can be brushed with nitro paint and enamel paint about 1-2 times, and the posture needs to be brushed with mold release agent. When the resin sand foundry is planning the posture lifting work, it should be set to dark hanging or in-mould hanging.

Without affecting the surface quality of the sand mold, it can also be planned on the core head or other parts of the attitude, the position of the spreader passes through the center of the attitude, and the lifting is stable. The skin seam design of the model is smaller than that of the water glass sand and clay sand molds. During the process of planning, the skin seam reduction modulus and the negative number of the classification are also smaller. Generally speaking, it is based on the previous process parameters. It is set according to 1-2%.

If the size of the general core is less than 500mm, the skin seam of the core can follow the design of 1mm. After the core is installed, the skin seam does not need to be repaired with sand, just brush 1-2 times. The paint can remove the skin seam, the installation of the core is also very convenient, and the scale alignment is relatively accurate.

Resin sand casting manufacturers use resin sand for modeling, and its strength is much higher than that of water glass sand and clay sand, especially the strength of back sand is more than that of water glass sand and clay sand. The amount of sand is much smaller than other previous sand modeling times, in view of this situation.

Relatively speaking, the tooling it uses is much smaller than before, and even the design of the box belt and box hole is much simpler than before. The box hole can be about 0.5-2 times larger than before, but on the box wall It is still necessary to set 200mm-300mm equidistant sand-hanging oblique bars, and 10-20mm wide sand-proof sinking bayonet should be set at the upper and lower box mouths.

Specifications for the use of precision casting

According to statistics, 60-70% of all castings are produced with sand molds, and about 70% of them are produced with clay sand molds. The main reason is that compared with other casting methods, sand casting has low cost, simple production process and short production cycle. Therefore, castings such as engine cylinder blocks, cylinder heads, and crankshafts of cars are produced by the clay wet sand process.

When the wet type cannot meet the requirements, consider using the clay sand surface dry sand type, dry sand type or other sand type. The weight of castings produced by clay wet sand casting can range from a few kilograms to tens of kilograms, while the castings produced by clay dry moulding can weigh tens of tons. Generally speaking, for medium and large castings, cast iron can be produced with resin no-bake sand molds, and steel castings can be produced with water glass sand molds.

Castings with accurate dimensions and smooth surfaces can be obtained, but the cost is high. Of course, the casting accuracy, surface finish, material density and metallographic arrangement, mechanical properties, etc. produced by sand casting are often poor, so when the castings have higher requirements for these properties, other casting methods should be used, such as investment (loss Wax) casting, die casting, low pressure casting, etc.

Casting methods such as low pressure casting, die casting and centrifugal casting are suitable for mass production due to the expensive equipment and molds. For small castings, a boxless high-pressure molding machine production line with horizontal or vertical parting can be selected, and the production efficiency of solid molding is high and the floor space is small; for medium parts, various boxed high-pressure molding machine production lines can be used. , Air punch modeling line.

In order to meet the requirements of fast and high-precision molding production lines, the core making methods can be selected: cold core box, hot core box, shell core and other core making methods. Medium-volume large castings can consider the use of resin no-bake sand for molding and core making. If the casting has multiple sections with different thicknesses, it is necessary to consider the design of multiple gating systems.

Conclusion

For more information about fetta lost wax casting,lost investment casting,lost wax casting parts, we are glad to answer for you.