Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

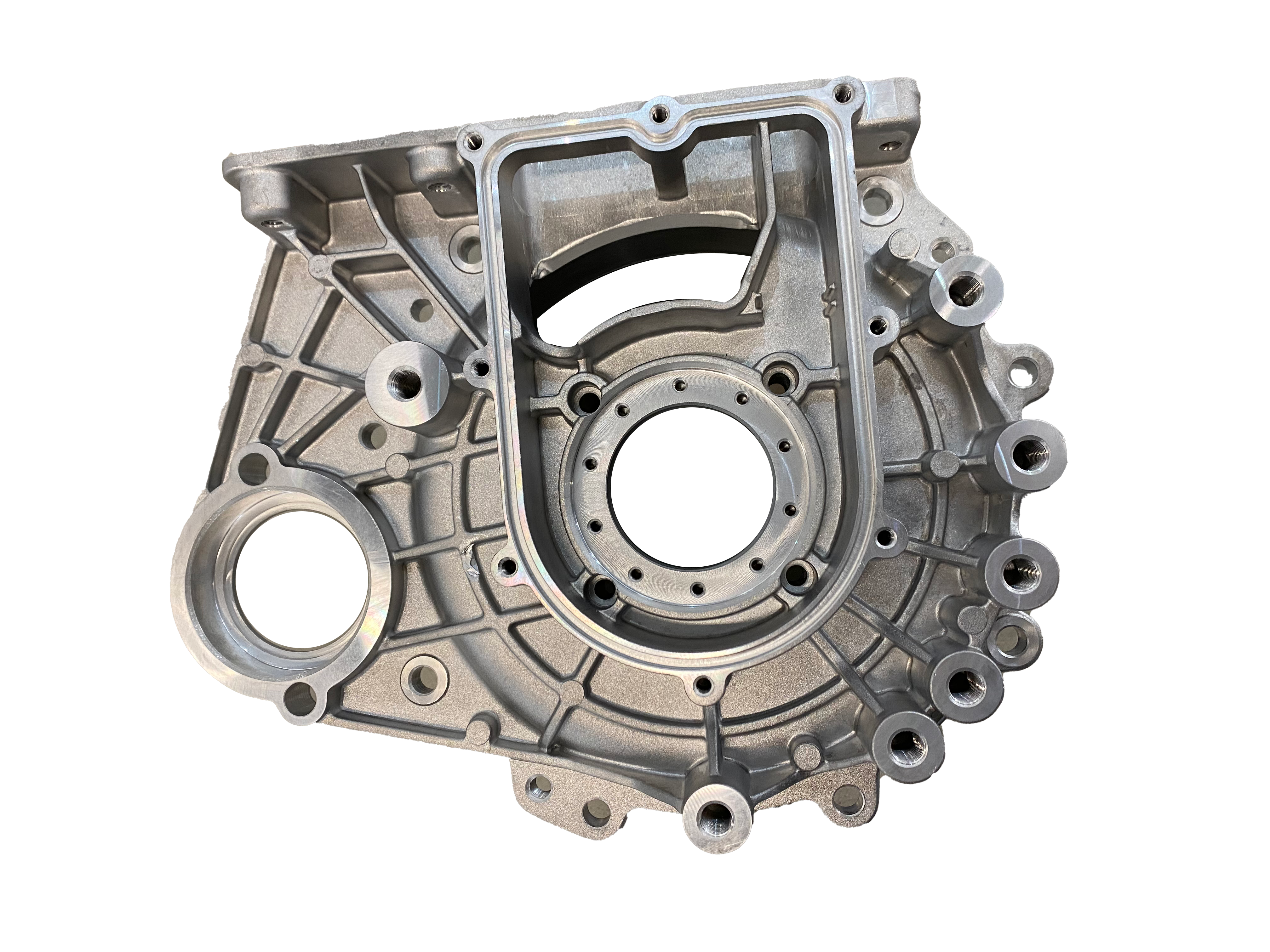

What Are the Components of the Die Casting Mold

The die-casting part is composed of two parts, one for covering and one for theme activity, and the part where they merge is called the analysis line. In hot chamber aluminum die casting, a part of the cover has a glue inlet, while in cold chamber aluminum die casting it is an injection port. Molten metal material can enter the mold from here, and this position corresponds to the injection nozzle in hot-chamber aluminum die casting or the injection chamber in cold-chamber aluminum die-casting. Part of the theme activity generally includes the swing rod and its runner.

To put it bluntly, the runner is a safe channel between the glue inlet and the mold core, and the molten metal material enters the mold core according to this safe channel. The cover part is generally attached to a stationary or front pin, while the subject part is attached to a moving pin. The core is divided into 2 core inserts, which are separate components and can be easily removed or installed from the mold according to the relative anchor bolts.

The grinding tools are very designed, and when the grinding tools are turned on, the castings are left as part of the themed event. That way, the swing rod that is part of the theme will release the casting. The swing rod is usually driven by a pin, and it will drive all the swing rods with exactly the same amount of energy, so as to ensure that the casting is not destroyed. When the casting is released, the pins are retracted to retrieve all the sway bars, fully ready for the next aluminum die casting. Because the casting is still at a high temperature when it is out of the mold, only the total number of pendulum rods is sufficient to ensure that the average working pressure on each pendulum rod is sufficiently small, and the casting will not be damaged. However, there will still be imprints on the pendulum rod, so it is necessary to carefully design the plan so that the position of the pendulum rod is not easy to cause too much damage to the operation of the casting.

What are the advantages and disadvantages of die casting

The advantages of aluminum die casting include the precision of the specifications of the castings. Generally, this lies in the forging raw materials. The typical standard value is the deviation of 0.1 mm at the initial 2.5 cm specification, and the deviation is increased by 0.002 mm for every 1 cm of increase. Compared with other forging processes, the surface of its castings is smooth and the semi-diameter of the arc is about 1-2.5 microns. Compared with the sandbox or die forging, castings with a wall thickness of about 0.75mm can be produced. It enables immediate forging of internal structures such as wire jackets, heated components, high toughness load bearing surfaces. Other advantages include that it can reduce or prevent secondary machining, faster production, casting compressive strength of 415Kpa, and the ability to forge high-flow metal materials.

The big defect of aluminum die-casting is its high cost. Compared with other forging methods, casting equipment and its abrasive tools and related parts are too expensive. Therefore, it is more economical to manufacture many commodities when manufacturing castings. Other defects include: this processing process is only suitable for metal materials with high liquidity, and the forging quality must be close to the middle of 30 grams and 10 kilograms. In general aluminum die casting, a batch of castings after forging will have porosity. Therefore, all quenching and tempering treatments or electric welding cannot be carried out, because the gas in the gap will rise under the effect of heat generation, which will cause internal small defects and the separation of the surface layer.

Conclusion

For more information about magnesium die casting process,jet cooling system die casting,sand casting and die casting, we are glad to answer for you.