Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

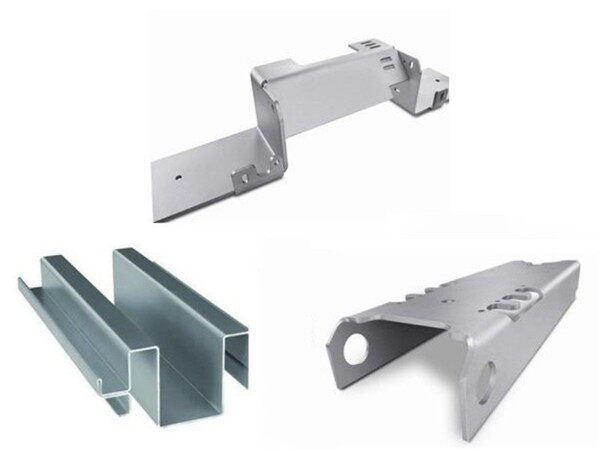

What are the Commonly Used Materials for Sheet Metal Processing?

Sheet metal processing includes traditional cutting, blanking, bending forming, and other methods and process parameters, as well as various cold stamping, die structures and process parameters, various equipment working principles and operation methods, as well as new stamping technology and new process. Sheet metal processing of parts is called sheet metal processing.

With the more and more extensive application of sheet metal, the design of sheet metal parts has become a very important part of the process of product development. Mechanical engineers must master the design skills of sheet metal parts, so that the designed sheet metal can not only meet the requirements of product function and appearance but also make the manufacturing of stamping tools simple and low cost.

The materials commonly used in sheet metal processing include cold rolled sheet (SPCC), hot rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (Cu) brass, red copper, beryllium copper, aluminum plate, aluminum profile, stainless steel (mirror, wire drawing surface, fog surface). According to the different functions of products, the materials selected are different, which generally need to be considered from the use and cost of products.

- Common cold rolled sheet SPCC

SPCC refers to the continuous rolling of steel ingots into steel coils or sheets of required thickness by the cold rolling mill. There is no protection on the surface of SPCC, and it is very easy to be oxidized when exposed to the air. Especially in a humid environment, the oxidation speed is accelerated, and dark red rust appears. When in use, the surface should be painted, electroplated, or otherwise protected.

- Galvanized steel sheet SECC

The substrate of SECC is a general cold-rolled steel coil, which becomes an electro-galvanized product after degreasing, pickling, electroplating and various post-treatment processes in the continuous electro galvanized production line. SECC not only has the mechanical properties and similar processability of general cold-rolled steel sheets but also has superior corrosion resistance and decorative appearance. It has great competitiveness and substitutability in the market of electronic products, household appliances, and furniture. For example, SECC is widely used in computer chassis.

- Hot dip galvanized steel plate SGCC

Hot dip galvanized steel coil refers to the semi-finished products after hot-rolled pickling or cold rolling, which are washed, annealed, immersed in the melting zinc bath with a temperature of about 460 ° C, and then coated with zinc, and then quenched, tempered, leveled and chemically treated. SGCC material is harder than SECC material, with poor ductility (avoiding deep pumping design), a thicker zinc layer, and poor weldability.

- Stainless steel SUS301

The content of Cr (chromium) is lower than SUS304, and the corrosion resistance is poor, but it can obtain good tension and hardness after cold processing and has good elasticity. It is mostly used for spring shrapnel and anti-EMI.

- Stainless steel SUS304

One of the most widely used stainless steels, because it contains Ni (nickel), it has more corrosion resistance and heat resistance than Cr (chromium) steel, has very good mechanical properties, no heat treatment hardening phenomenon, and has no elasticity.

For more information about cnc sheet metal fabrication, cnc sheet metal bending, cnc machine for sheet metal fabrication, plz feel free to contact us.