Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

Precision Metal Processing: Several Points You Need to Know(1)

For prototype and end-use parts, accuracy is a very important aspect of metal processing. Accuracy means that the appearance and feel of the parts you get are the same as those you designed, and there are no errors that may affect the mechanical function.

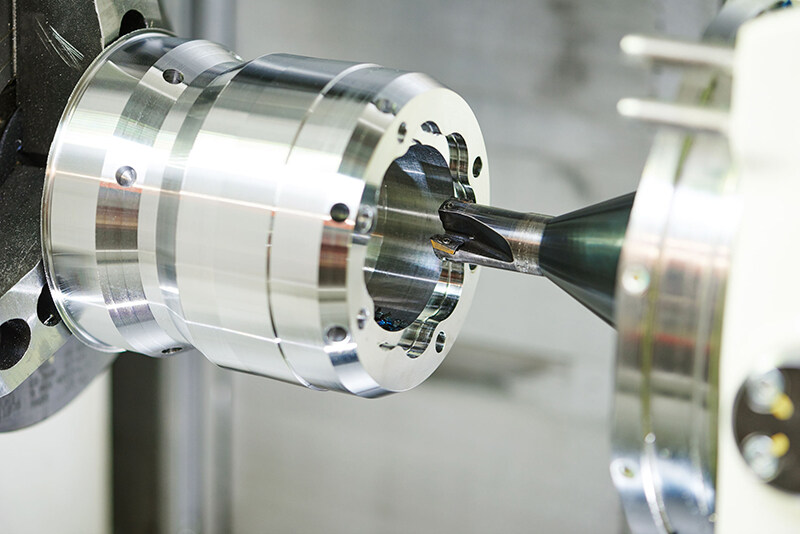

Due to the rise of CNC machine tools, metal processing is now more accurate than ever before. The machinist can use the computer to program the cutting tool path to the micrometer, which almost eliminates the inaccuracy caused by human errors. As long as the CNC machine is set correctly, it should cut metal parts with high precision.

But many factors affect the accuracy of metal processing. Machine quality, material selection, and even room temperature can play a role. Some customers may have very different accuracy requirements for other customers.

This blog discusses the context of precision metal processing and explains the concepts of precision, precision, and tolerance.

What is machining accuracy?

Although precision and precision seem to be synonymous, they have different meanings in processing. Therefore, it is important to understand the meaning of the different terms we use.

In the context of metal processing, accuracy is the degree to which the machine can match the measured values specified in the design.

If the machine can cut the precise position specified in the design, it has high accuracy.

If it occasionally misses the target, but on average it hits the right position, then we can say that it still has high accuracy.

What is machining repeatability or machining accuracy?

Machining accuracy refers to the similarity of measured values between multiple attempts or multiple copies of parts.

In other words, if a machine accurately hits the same point on 100 copies of a part, it has high accuracy.

This is different from precision because precision does not pay special attention to whether the "point" is the same as the point specified in the design! A machine can be very accurate, even if it always cuts 3 mm to the left of the expected mark.

It is important to have accuracy and accuracy at the same time.

Accuracy means that you are reaching the coordinates specified in the design, and accuracy means that you are hitting them consistently on multiple units.

What is machining tolerance?

In machining, tolerance refers to the deviation from the value of cutting. Therefore, it is related to the accuracy, but it is the value specified by the customer, not the attribute of the machine itself.

If the customer requires a feature of the part to be very consistent between units, they will specify strict tolerances on the feature to allow the minimum deviation. In practice, this means that the machine must be operated more slowly and carefully.

If a looser tolerance is specified - for example, on nonmechanical features - machining can be carried out faster.

Although the tolerance is defined by the customer, the machine usually specifies its standard tolerance and the minimum possible tolerance.

Make a purchase of aluminum precision machining, cnc precision machining company, precision machining manufacturer from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.