Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

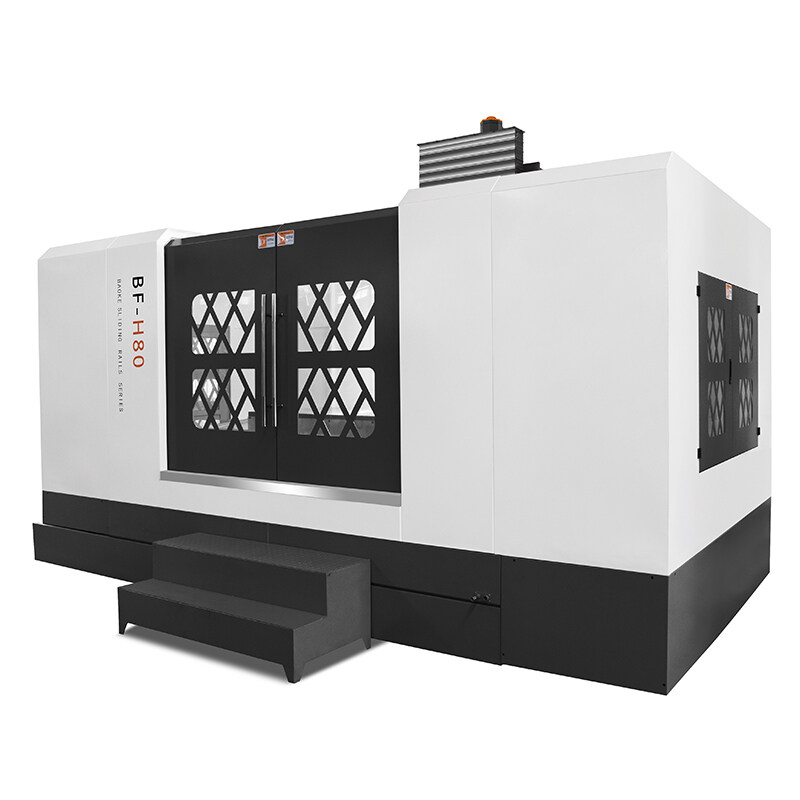

Precautions for Correct Operation and Maintenance of CNC Horizontal Machining Center

CNC horizontal machining center is widely used, but the improper operation will cause machine failure or other accidents. Only the correct number of operations can avoid damage to the machine tool and improve the working efficiency of the machine tool. Generally, the installation, use, maintenance, inspection, control, oil supply, or cleaning of CNC horizontal machining centers require personnel to operate. These personnel must have received systematic and comprehensive training before they can operate, and they also need to operate by the operation manual.

The machine tool is marked with the words "attention", "warning" and "danger". For different marks, the meaning is different, and the degree of danger is also different. For example, marking danger on it means that abnormal operation will cause injury to the operator or serious mechanical failure, so the operator must strictly abide by the marks on the machine tool to operate. Limited signs, such as the safety signs on the spindle head unit, remind the operator to close the door before or during operation and not walk beside the machine tool. If the rapidly rotating processing workpiece breaks and flies out of the machine tool, it will cause serious personal injury.

During the operation, it is necessary to prevent electric shock and electrical accidents caused by the high voltage in the main electrical cabinet, control panel, transformer, motor, terminal box, or operation panel and its area. At the same time, it is also necessary to pay attention not to touch the switch of the machine tool with wet hands to prevent electric shock. It needs to be checked once a quarter to prevent the line from aging or some machine tool function errors, to prevent accidents from happening in the future, and control the occurrence of accidents from the source. At the same time, prepare a solid workbench around the machine tool, and do not slide its surface. Only by carrying out the correct detection, and then operating according to the operation manual in the process of operation, can the machine tool operate better and prolong its working life of the machine tool.

The correct operation and use of a CNC horizontal machining center can prevent abnormal wear and tear, avoid sudden failures, and do a good job in daily maintenance, which can maintain the good technical state of the machining center, delay the deterioration process, and ensure safe operation.

Today, we will introduce the maintenance items from the mechanical parts:

- Maintenance of tool magazine and tool changing manipulator it is strictly forbidden to install overweight or overlong tools into the tool magazine of the CNC horizontal machining center to avoid tool dropping or collision between tools and workpiece and fixture when changing tools by manipulator; Always check whether the zero return position of the tool magazine is correct, and check whether the position of the tool change point of the spindle is in place, and adjust it in time; When starting up, the tool magazine and manipulator should be operated empty, and check whether all parts work normally, especially whether all travel switches and solenoid valves operate normally; Check whether the locking of the tool on the manipulator is reliable, and handle it in time if it is abnormal.

- Maintenance of the main drive chain regularly adjusts the tightness of the spindle drive belt of the CNC horizontal machining center to prevent rotation loss caused by belt slip; Check and maintain the lubrication of the main shaft, replenish the oil in time, and clean the filter regularly; The tool clamping device in the spindle will produce clearance after long-term use, which will affect the clamping of the tool. It is necessary to adjust the displacement of the hydraulic cylinder piston in time.

- Maintenance of ball screw thread pair regularly check and adjust the axial clearance of ball screw thread pair to ensure the reverse transmission accuracy and axial stiffness; Regularly check whether the connection between the lead screw and the bed is loose; If the lead screw protective device is damaged, it should be replaced in time to prevent dust or chips from entering.