Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

lost foam aluminum casting,foam for casting,lost wax casting sculpture

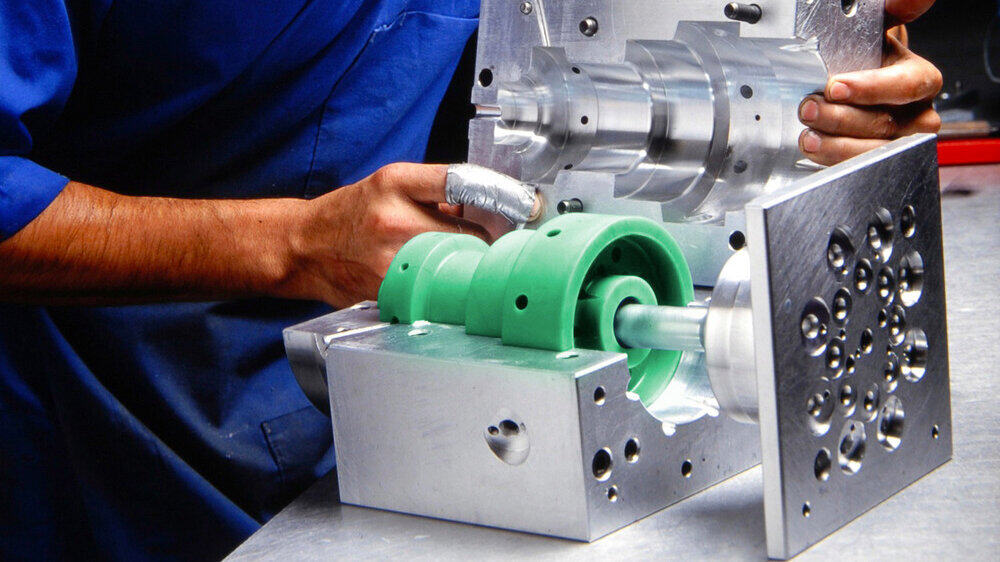

Foam for casting (also known as solid casting) is a type of precision casting. It is a new casting method that combines paraffin or foam models similar in size and shape to castings into model clusters, after brushing refractory paint and drying, burying in dry quartz, pouring under negative pressure making the model gasify, and then the liquid metal occupying the position of the model, and finally solidification and cooling.

Different from lost wax casting, lost foam casting has the advantages of good casting accuracy and less pollution. However, during the casting process, it is easy to have pores or sand inclusions in the casting due to technological operations and other reasons. Today, we will analyze the main causes of porosity and sand inclusion in lost foam casting.

Common problems about lost foam aluminum casting

- Due to the unreasonable design of the gating system, the filling speed of the molten metal is greater than the speed of the bubble gasification and gas discharge, resulting in the filling front encapsulating the gasification residue in the metal liquid and re-gasifying to form a black decomposition body on the inner wall.

- The opening position of the runner is unreasonable, and a dead corner area is formed when filling the mold. Due to the gas pressure in the cavity, the gasification residue accumulates in the dead corner to form pores, and the cross-sectional area of the runner is too large.

- The pouring speed is too slow, the sprue cup cannot be filled, the sprue is exposed, the air is involved, the slag is sucked, and the entrained pores and slag holes are formed.

- The foam model is gasified and decomposed to generate a large amount of gas and residues that cannot be discharged from the mold in time. The foam, coating layer and filling dry sand are not well dried. Under the high temperature of the liquid metal, a large amount of hydrogen and oxygen are cracked and penetrated into the casting. is the main reason for the formation of pores.

- The connection between the sprue cup and the sprue and the pouring system is not well sealed, especially the connection between the sprue and the sprue cup is not well sealed, and it is easy to form sand inclusions and pores under the action of negative pressure.

- The particle size of the molding sand is too fine, the dust content is high, the air permeability is poor, and the negative pressure is distorted due to the internal blockage of the negative pressure pipeline, so that the negative pressure value of the sand box is far lower than the negative pressure value of the indicator, and the vapors cannot be discharged from the coating in time, resulting in the formation of pores or wrinkles.

- The deoxidation of molten steel is poor, the slag removal in front of the furnace, in the furnace and in the bag is not clean, the time for stabilizing the molten metal is too short, the slag blocking during the pouring process is not strong, and the pouring process is unreasonable, resulting in slag holes.

- The air permeability of the coating is poor or the negative pressure is insufficient, the air permeability of the filling sand is poor, and the gas in the cavity cannot be discharged in time, and pores are formed under the filling pressure.

- The capacity of the sprue cup is too small, and the molten metal forms a vortex, which invades the air to generate pores.

- The pouring temperature is low, the molten metal at the filling front cannot fully vaporize the foam, and there are too many undecomposed residual substances, which cannot be floated to the riser and solidified in the casting.

The above are the common causes of pores and sand inclusions in lost foam casting that we have sorted out for you. For more solutions, please feel free to contact us. Certainly, we also have lost wax casting sculpture for sale, click here!