Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

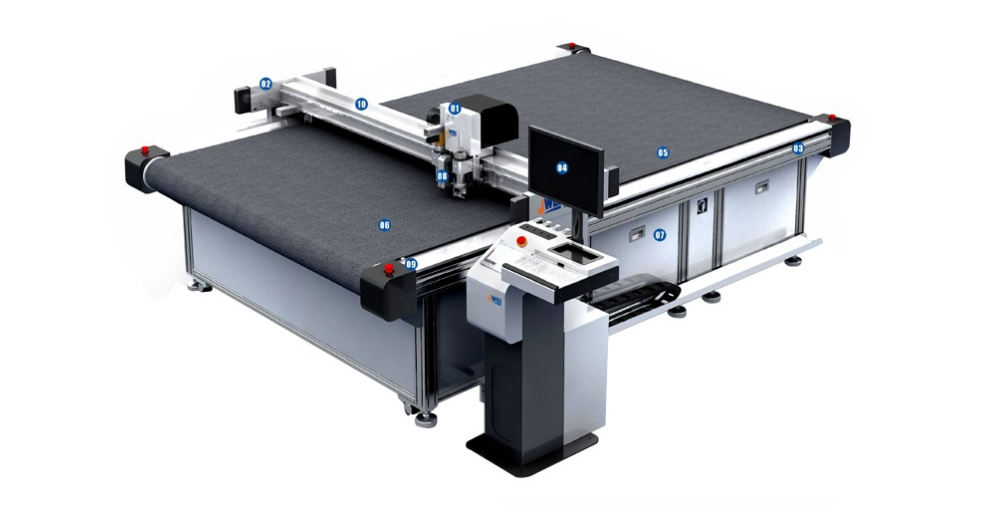

Application Method of CNC Cutting Machine

I believe you have heard and understood about CNC cutting machines. Using CNC cutting machine can help us cut things faster and cut well, but there is a premise that we have to be skilled in using CNC cutting machine.

Next, I will introduce the use of a CNC cutting machine.

Feeding

Before using the CNC cutting machine, we need to put an iron plate to be cut on the material rack first. We need to pay attention to the special level of the material rack plate, which cannot be different in height. If the iron plates are parallel, we can find the parallel according to the track of our CNC cutting machine.

Inspect

Before working, we need to check the use of the CNC cutting machine to see if there is any problem. We can start the machine only after it is sure that there is no problem, to avoid accidents. We can start the machine and use it normally only after we check that there is no obstacle on the walking track.

Select cutting method

If it is a dual-purpose cutting machine, it is divided into a plasma cutting machine and a flame cutting machine. We need to decide which cutting method to use according to the thickness of the cutting iron plate. Each of the two has its advantages. You can choose for yourself. If you choose to switch on the equipment, if there is only one use method, this step can be ignored.

Numerical control system

Open the CNC system, select graphics management, find the graphics we need to cut, set the size we need to cut, and confirm.

Drawing software

If there is no cutting figure in the system, we need to use drawing software to draw and then use nesting software to nest.

Nesting software

When nesting, we can adjust the cutting sequence. The specified function above is to set the size according to our workpiece, arrange the graphics, and then save them. Put them in our USB flash disk, and then insert the USB flash disk into the CNC system for reading. When everything is ready, press the start button, that is, the start button on the CNC cutting machine, Just start cutting.

Methods of Improving CNC cutting efficiency

- The instability of the CNC system will lead to slow cutting.

Due to the heating of the CPU and hard disk of the CNC system, the system is unstable and cannot work stably; Or the fan is worn, the hard disk vibrates or is infected with virus damage, which leads to production stagnation. There may also be defects in the cutting control software of the CNC system, failures, or cutting errors, which will also delay cutting production and affect cutting quality.

- Not using nesting software leads to low material utilization.

Instead of using nesting software, call parts or read in parts on the CNC system for manual programming and local cutting, which is not only a waste of time but also a waste of materials. Therefore, installing nesting software saves time and materials.

- There is no automatic cutting process and cutting parameter database on the CNC system.

The operator can only rely on experience and eye observation to operate the CNC cutting machine manually, and can not achieve automatic perforation and automatic cutting, so the production efficiency of the cutting machine is naturally very low.

- Improper cutting method.

In the cutting setting, the cutting method used is too simple. Each part should be perforated and cut completely. Efficient cutting methods such as common edge, borrowing edge, and bridging are not used, resulting in low cutting efficiency and a serious waste of cutting nozzle consumables (especially plasma cutting nozzle).

For more information about cnc cutting near me, cnc cutting price, cnc cutting services near me, plz feel free to contact us.