Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

Advantages and Disadvantages of Lost Wax Casting and Sand Casting

China's bronze culture has a long history and has been formed for about 4,500 years. The heyday of the Bronze Age (Xia Dynasty to Warring States Period) lasted for 1,600 years. There are many kinds of bronze ware from ritual utensils to daily necessities. Due to the unique beauty of bronze, many kinds of handicrafts were produced in the later period. The patterns and shapes of bronze handicrafts in each era are different, and the details are even more breathtaking.

The lost wax casting method is a casting method that can perfectly present the beauty of bronze details. So, do you know the advantages and disadvantages of lost wax casting and sand casting? Let's discuss it together.

Sand casting

The sand casting method is to use clay-bonded sand as the modeling material to produce cast copper sculptures. Since its application thousands of years ago, most countries in the world, including the United States and Japan, are using the sand casting method to produce cast copper handicrafts.

Sand casting is a production method in which molten metal is poured into the cavity of a mold and cooled to obtain a product. The raw material of the sand mold is mainly sand, which is mixed with binder and water. Therefore, the sand casting method is simple and easy to operate, and the material production cost is low. It can be applied to the production of copper, plastic and other handicrafts. The cost and manpower consumed are low.

However, although the sand casting process is simple, there are many factors that are constantly changing, such as the treatment of old sand, the addition of new sand and auxiliary materials. There may be problems. In addition, sand casting is more suitable for the manufacture of blanks, because its production process determines that this manufacturing method cannot achieve perfection in details.

Lost wax casting

Lost wax method and pottery method are known as the two major bronze manufacturing methods. They are specialized precision casting methods for bronze and other metals.

The method is: use beeswax to make a casting model, and then use other refractory materials to fill the mud core and form the outer mold. After heating and baking, the wax film is completely melted and lost, so that the entire casting model becomes an empty shell, and then poured into it. The molten liquid is cast into objects. It is one of the three major casting technologies in ancient China. The materials are lime tri-bond and carbon mud, which are simple and easy to obtain. With the development of science and technology, it was gradually replaced by zircon, zircon sand and mullite.

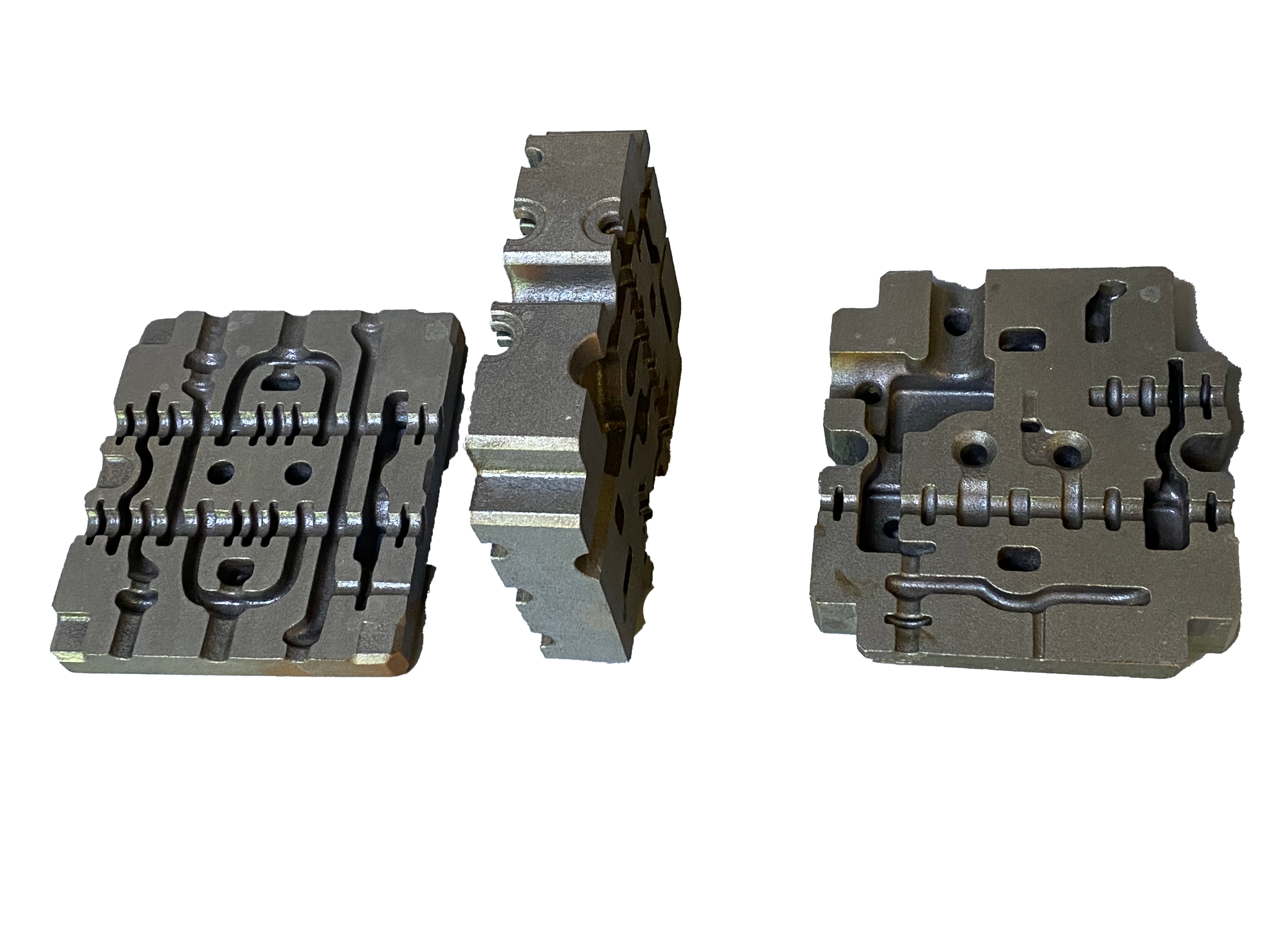

Most of the ancient Chinese dings, furnaces, musical bells, and seals were made by the lost wax method. Intersecting with the sand-turning method, the lost-wax method does not need to take out the mold from the sand mold, so it can cast very complex, fine and beautiful handicrafts.

For handicrafts, unique details and fine grinding are essential. A high-quality bronze handicraft naturally pays attention to the perfection of every detail and the fineness of the items, so that they can be more valuable for viewing and collection. The fly in the ointment is that the lost wax process is complicated and consumes a lot of artisan energy. However, a perfect handicraft must pay more effort and hardships, which is also the value of handicrafts.

Conclusion

For more information about oem lost wax casting,best lost wax casting,lost wax casting system, we are glad to answer for you.