Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

24 Kinds of Metal Materials Commonly Used in Machining and their Characteristics!(2)

6. 65Mn -- common spring steel

Application examples: various flat and round springs, cushion springs, spring springs in small sizes, spring rings, valve springs, clutch springs, brake springs, cold coil springs, snap springs, etc.

7. 0Cr18Ni9 - the most commonly used stainless steel (American steel 304, Japanese steel SUS304)

Characteristics and application: it is the most widely used stainless and heat-resistant steel, such as food equipment, general chemical equipment, and original energy industrial equipment.

8. Cr12 - common cold working die steel (American steel D3, Japanese steel skd1)

Characteristics and application: Cr12 Steel is a kind of widely used cold working die steel, which is a high carbon and high chromium ledeburite steel. The steel has good hardenability and wears resistance; Because the carbon content of Cr12 Steel is as high as 2.3%, it has poor impact toughness, is easy to embrittle, and is easy to form uneven eutectic carbides; Because Cr12 Steel has good wear resistance, it is mostly used to manufacture cold stamping dies, punches, blanking dies, cold heading dies, punches and dies of cold extrusion dies, drill sleeves, gauges, wire-drawing dies, stamping dies, thread rolling plates, deep drawing dies, and cold stamping dies for powder metallurgy, which requires high wear resistance and is subject to small impact loads.

9. DC53 - common cold working die steel imported from Japan

Characteristics and application: high strength and toughness cold working die steel, steel grade of Japanese Datong special steel (Zhuzhou) manufacturer. After high-temperature tempering, it has high hardness, high toughness, and good wire cutting performance. For precision cold stamping dies, drawing dies, threading dies, cold blanking dies, punches, etc.

10. Dccr12mov - wear-resistant chromium steel

Compared with Cr12 Steel, the carbon content of domestic steel is lower, and with the addition of Mo and V, the uneven carbide is improved. Mo can reduce carbide segregation and improve hardenability, and V can refine grains and increase toughness This steel has high hardenability. The section can be completely quenched below 400mm. It can still maintain good hardness and wear resistance at 300~400 ℃, has higher toughness than Cr12, has small volume change during quenching, and has high wear resistance and good comprehensive mechanical properties Therefore, we can manufacture all kinds of molds with a large cross-section, complex shape and large impact, such as ordinary drawing die, punching die, blanking die, trimming die, edging die, wire drawing dies, cold extrusion dies, cold cutting scissors, circular saw, standard tools, measuring tools, etc.

11. SKD11 - ductile chromium steel

Japanese Hitachi plant production has technically improved the casting structure in steel and refined the grain Compared with Cr12MoV, the toughness and wear resistance are improved The service life of the die is prolonged.

12. D2 - high carbon and high chromium cold-worked steel

Made in the United States, it has high hardenability, hardenability, wear resistance, good high-temperature oxidation resistance, good corrosion resistance after quenching and polishing, and small heat treatment deformation. It is suitable to manufacture all kinds of cold working molds, cutting tools, and measuring tools that require high precision and long life, such as drawing dies, cold extrusion dies, cold shear knives, etc.

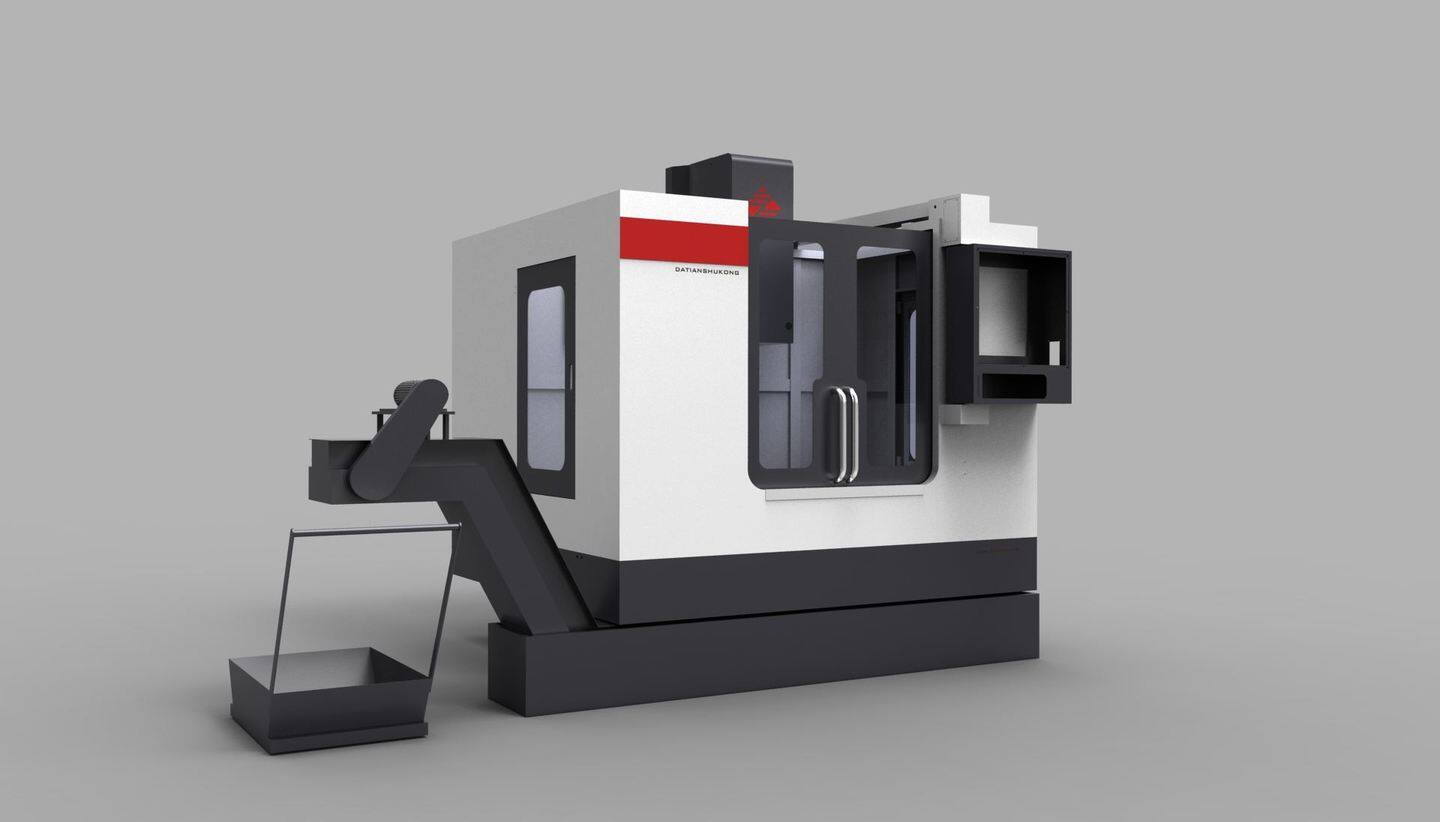

Searching for a 3d cnc milling machine, cnc 3018 pcb milling, 4th axis milling manufacturer from China, you can get high-quality products at a nice price.