Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

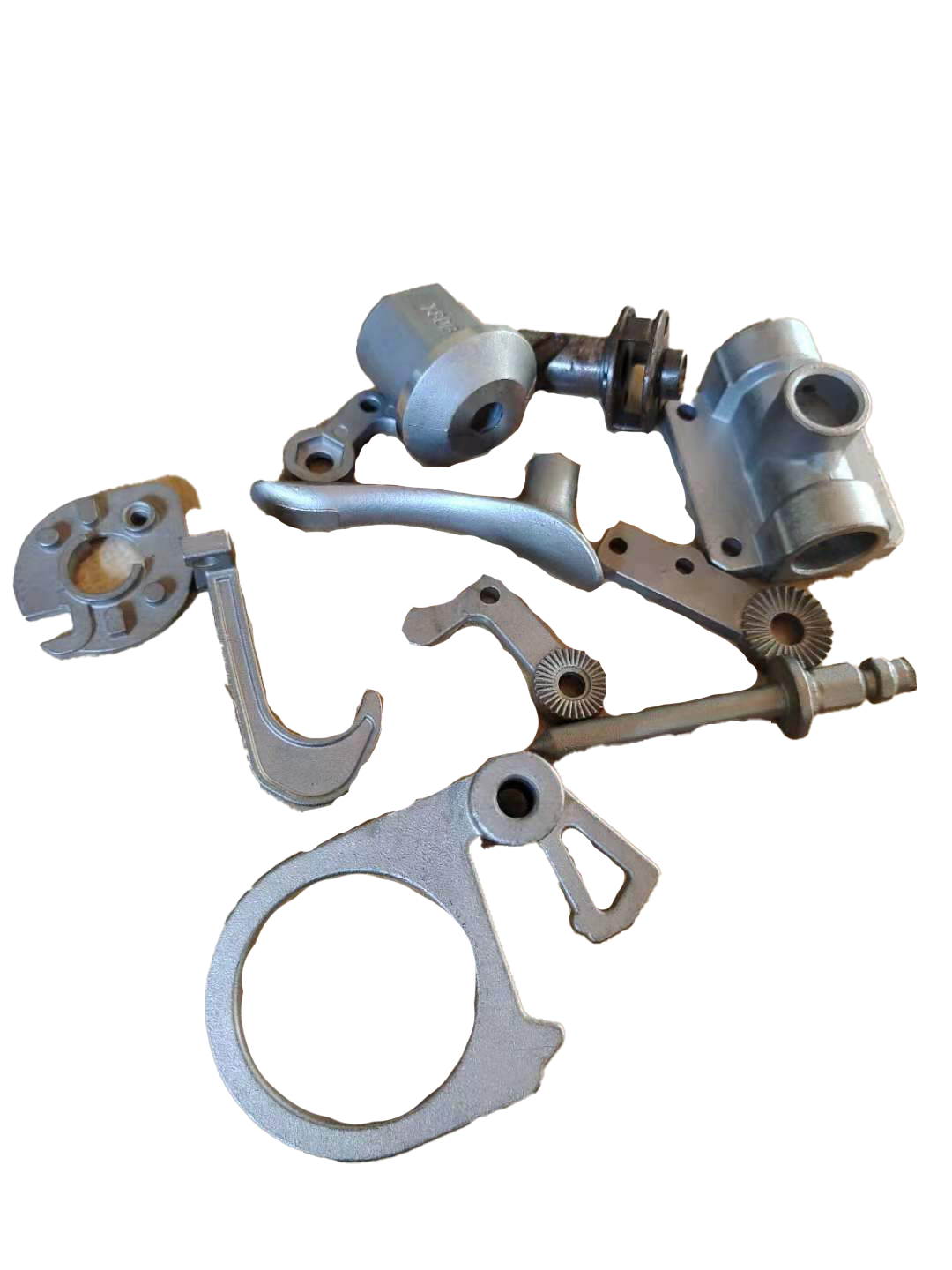

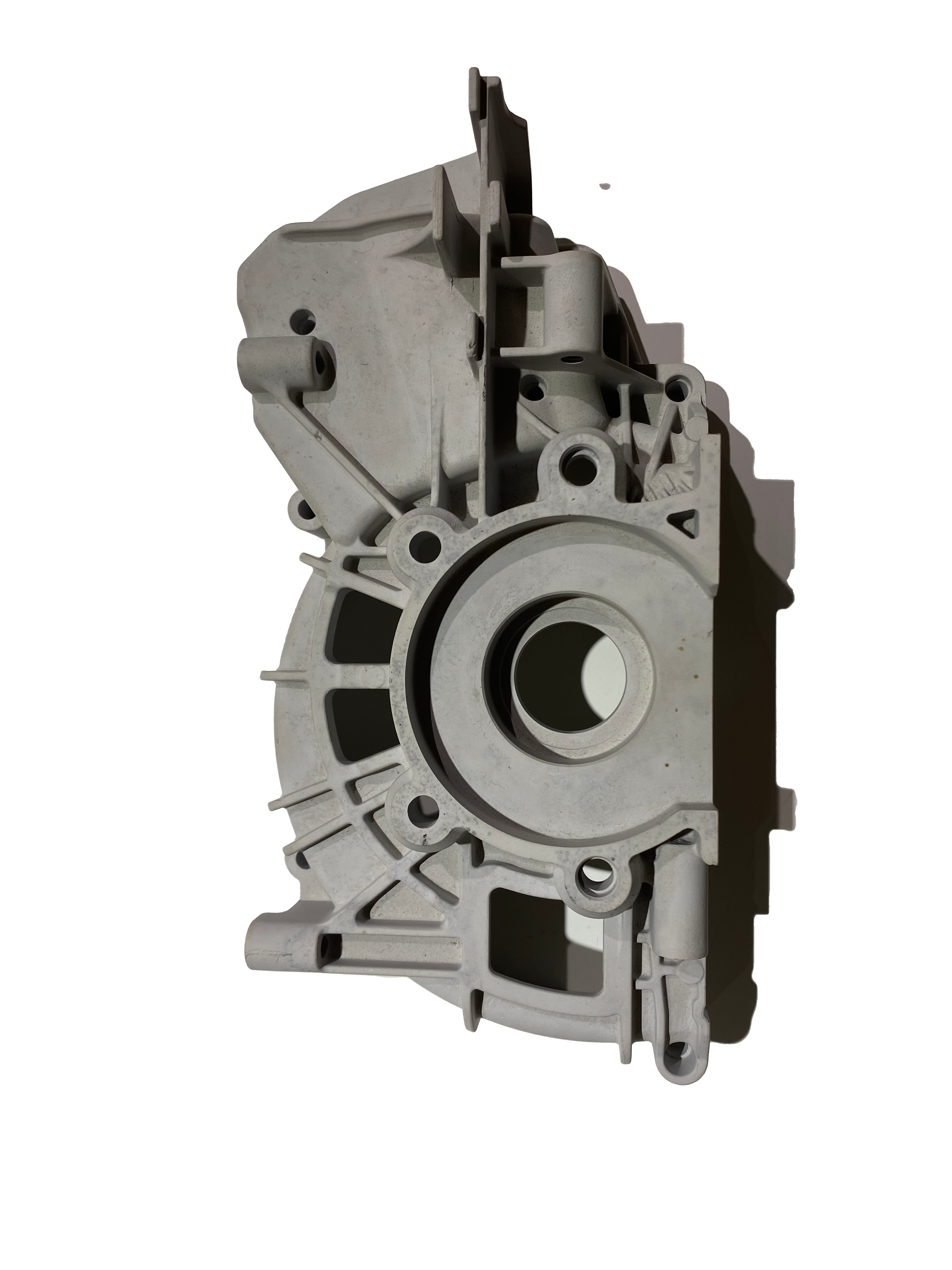

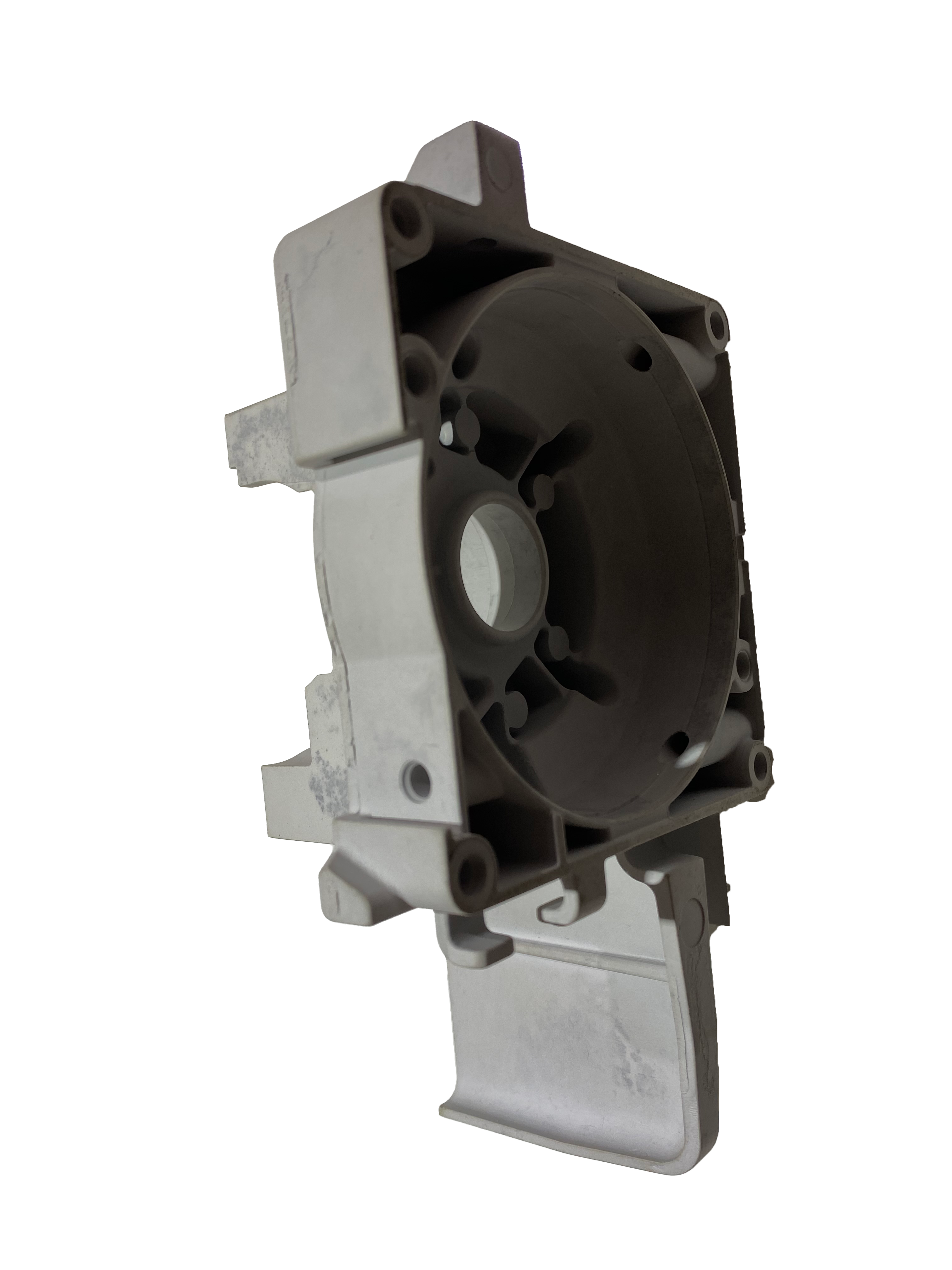

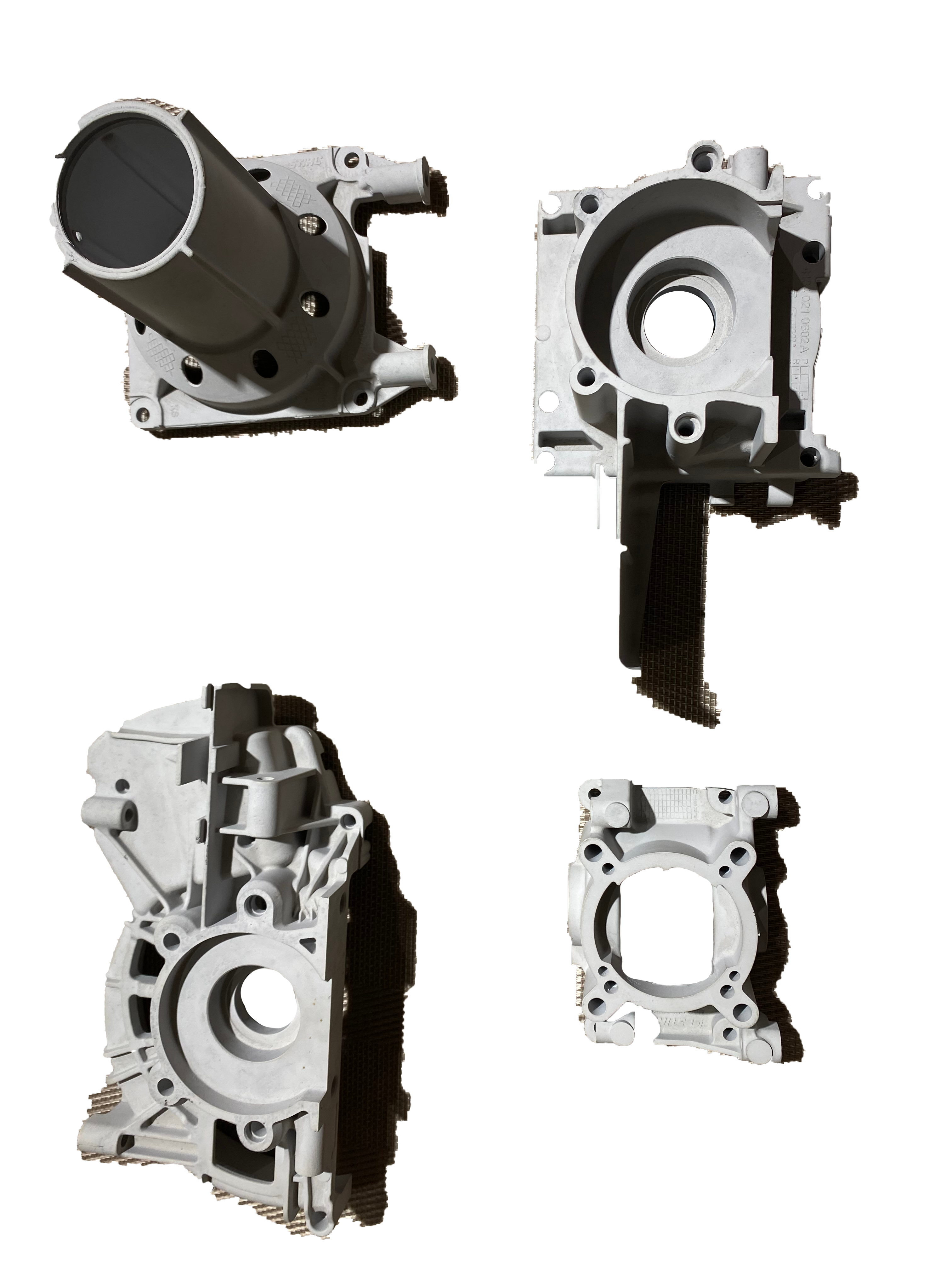

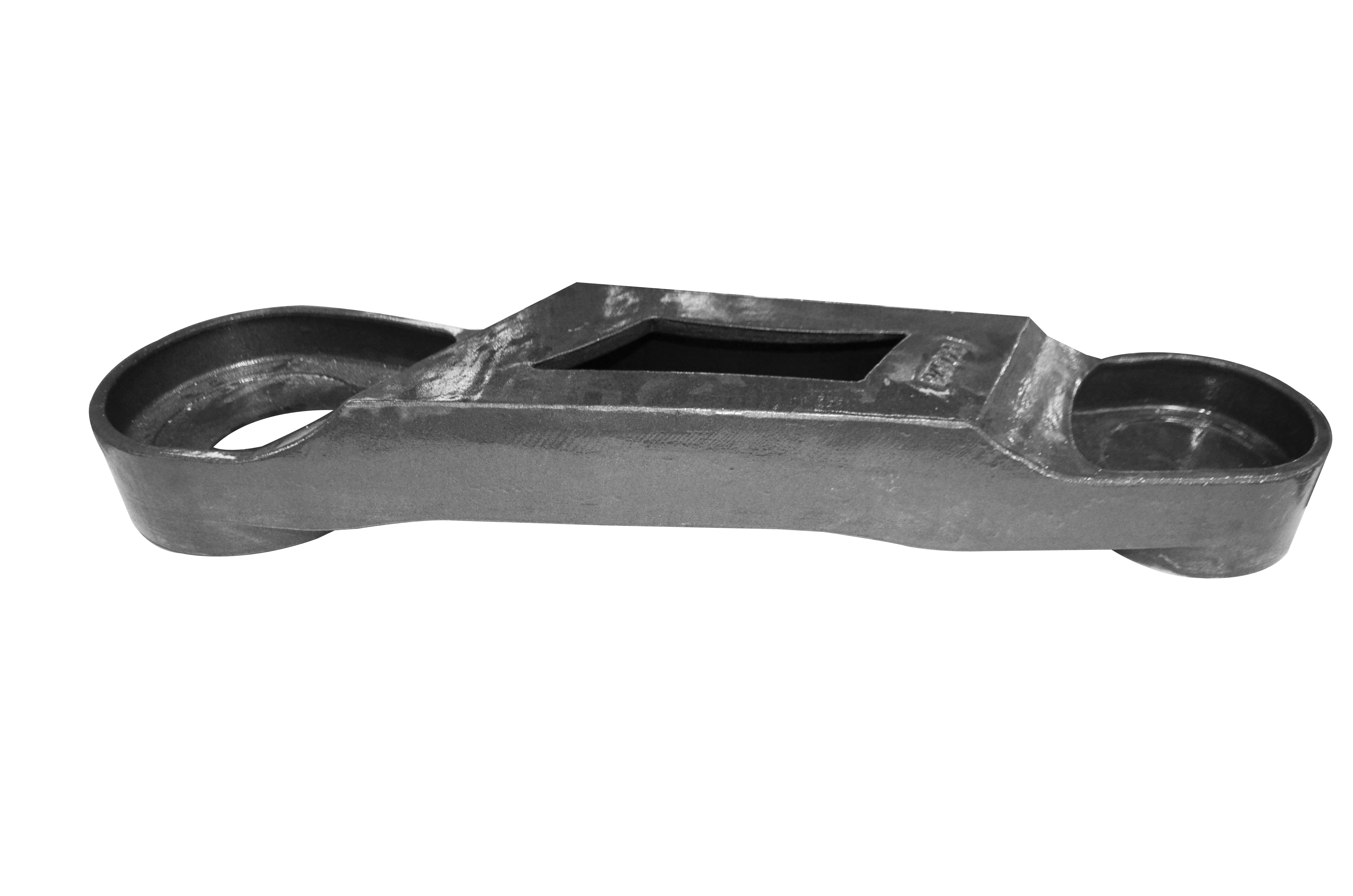

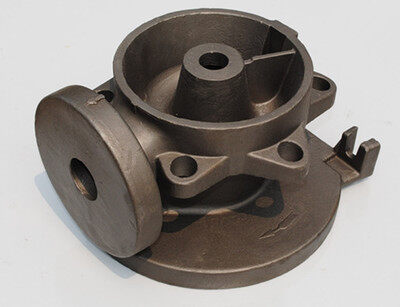

Lost wax casting

Investment casting, also referred to as lost wax casting, involves procedures like pressing wax, mending wax, putting together trees, dipping slurry, melting wax, and casting molten metal. Making a wax mold of the component to be cast using wax, then covering it with mud to create a mud mold, is known as lost wax casting. Put the dried clay mold in hot water to melt the internal wax mold.

Descriptions of Lost Wax Casting

Lost wax casting, also known as investment casting, includes processes like pressing wax, repairing wax, assembling trees, dipping slurry, melting wax, casting molten metal, and post-treatment. Lost wax casting is to use wax to make a wax mold of the part to be cast, and then coat the wax mold with mud, which is a mud mold. After the clay mold is dried, put it in hot water to melt the interior wax mold. Take out the clay mold from the melted wax mold and fire it into a pottery mold. Generally, a pouring port is left when making a mud mold, and then molten metal is poured from the pouring port. After cooling, the required parts are made.

The material is made into a pattern, and the surface of the pattern is covered with several layers of refractory material to make a mold shell, and then the pattern is melted and discharged from the mold shell to obtain a mold without parting surface. After high temperature roasting, it can be filled with sand and poured. Due to patterns are widely made of waxy materials, investment casting is often referred to as "lost wax casting".

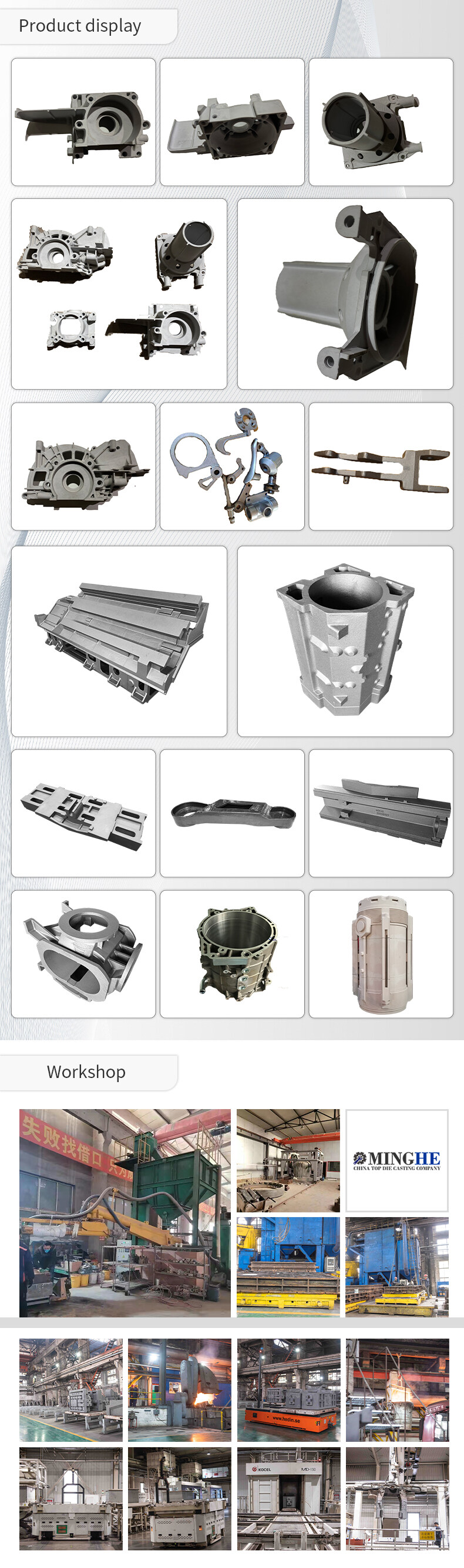

The Lost Wax Casting Process of MINGHE

According to the industry and application, the lost-wax casting process has some differences, but it generally is composed of the following steps. Cast components can be made from a wax model itself, which is called the direct method, or from replicas of the original wax model, which is called the indirect method.

- Model creating: The artist carves a design out of wax. The size and complexity of the wax model is restricted to the wax carver’s skill, and the capacity of his casting equipment. When shaping your pattern, make sure to consider any anticipated shrinkage when the metal cools. Patterns may also be gated with sprues to allow the molten metal to flow into the mold. This is especially important if your design contains small and intricate elements that may not fill with metal during the casting process.

- Making a mold: A caster then casts this model and polishes the casting to produce a “master” pattern. The master model is used to make a wax mold out of rubber, which is heated and “vulcanized” around the master casting to make a flexible wax mold. When working with dry materials, make sure that your work area is well ventilated, and wear a respirator when working with dry investment.

- Producing wax patterns: Molten wax is injected or sometimes poured into the rubber mold. This can be done over and over to make copies of the original design.

- Assembling the wax pattern: Sprues are added to the wax copies and they’re connected to create a tree-like structure, which provides paths for the molten wax to flow out and molten metal to later fill the cavity.

- Applying investment materials: The wax tree is either dipped into a slurry of silica, or put into a flask and surrounded by the liquid investment plaster.

- Burnout: After the investment material dries, the flask is placed upside down into a kiln, which melts the wax leaving a negative cavity in the shape of the original model.

- Pouring: The investment mold is further heated in a kiln to reduce the temperature difference with the molten metal. Metal is melted and then poured, using gravity or vacuum pressure to pull the metal into the cavity.

- Devesting: Once the molten metal has cooled somewhat, the investment mold is quenched in water to dissolve the refractory plaster and release the rough casting. . The sprues are cut off and recycled, while the casted parts are cleaned up to remove signs of the casting process.

- Finishing: The casted parts are filed, ground, machined, or sandblasted to achieve final geometry and surface finish. Where necessary, the cast parts are also heat-treated to enhance the mechanical properties of the material.

FAQ

How to order?

First, Customer could send us your sample or drawing, such as 2D and 3D drawing(IGS or STP format). Second, Our engineers will check the drawing carefully and then provide you a better price. Thirdly, If you accept, then order confirmed.

Where is your factory?

Our factory located on Dongguan which is a beautiful city which is very near Guangzhou and Shenzhen. You can fly to Shenzhen Bao'an International Airport (ZGSZ) or Guangzhou Baiyun International Airport (ZGGG), we will pick you up at the airport.

Are you a factory or trade company?

We are a factory. We provide you one-stop service, from mold design to finish part.

How to ship?

The sample of die casting and CNC machining or small order is usually sent by TNT, FEDEX, UPS etc, and the big order is sent by air or sea after confirmation of clients.

What is your terms of payment ?

Die casting mould payments: advanced payment 40% after contract signing;

The 60% balance will be paid after approval of mould by customer.

The payment term of die casting orders: T/T, 30% as deposit be paid before production by T/T, 70% be paid before delivery.